6.4. When ensuring acceptable microclimate values at workplaces:

· the difference in air temperature in height should be no more than 3°C;

· the horizontal air temperature difference, as well as its changes during the shift, should not exceed:

for work categories Ia and Ib - 4°C;

for work categories IIa and IIb - 5°C;

for work category III - 6°C.

In this case, the absolute values of the air temperature should not go beyond the values indicated in the table. 2 for certain categories of work.

6.5. When the air temperature in the workplace is 25°C and above, the maximum permissible values of relative air humidity should not exceed the following limits:

70% - at an air temperature of 25°C;

65% - at an air temperature of 26°C;

60% - at an air temperature of 27°C;

55% - at an air temperature of 28°C.

6.6. At an air temperature of 26-28°C, the air speed indicated in the table. 2 for the warm period of the year, must correspond to the range:

0.1-0.2 m/s - for work category Ia;

0.1-0.3 m/s - for work category Ib;

0.2-0.4 m/s - for work category IIa;

0.2-0.5 m/s - for work categories IIb and III.

6.7. The permissible values of the intensity of body radiation for workers in the workplace from industrial sources heated to a dark glow (materials, products, etc.) must correspond to the values given in Table. 3.

Table 3

Permissible values and intensity of thermal irradiation of the body surface of workers working from industrial sources

| Irradiated body surface, % | Thermal irradiation intensity, W/m, no more |

| 50 or more | 35 |

| 25-50 | 70 |

| no more than 25 | 100 |

6.8. The permissible values of the intensity of thermal radiation for those working from radiation sources heated to a white and red glow (hot or molten metal, glass, flame, etc.) should not exceed 140 W/m2. In this case, more than 25% of the body surface should not be exposed to irradiation, and the use of personal protective equipment, including face and eye protection, is mandatory.

6.9. In the presence of thermal radiation of workers, the air temperature in the workplace should not exceed the following values, depending on the category of work:

25°С - for work category Ia

24°С - for work category Ib;

22°С - for work category IIa;

21°С - for work category IIb;

20°С - for work category III.

6.10. In industrial premises in which permissible standard values for microclimate indicators cannot be established due to technological requirements for the production process or economically justified inexpediency, microclimate conditions should be considered harmful and dangerous. In order to prevent the adverse effects of the microclimate, protective measures should be used (for example, local air conditioning systems, air showers, compensation for the adverse effects of one microclimate parameter by changing another, special clothing and other personal protective equipment, heating rest rooms, regulation of work hours, in particular, breaks in work, reduction of working hours, increase in vacation duration, decrease in length of service, etc.).

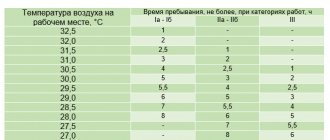

6.11. To assess the combined impact of microclimate parameters in order to implement measures to protect workers from possible overheating, it is recommended to use the integral indicator of the thermal load of the environment (THL), the values of which are given in Table. 1 applications 2.

6.12. To regulate the working time within a work shift in microclimate conditions with air temperatures at workplaces higher or lower than permissible values, it is recommended to follow the table. 1 and 2 appendices 3.

7.1. Measurements of microclimate indicators in order to monitor their compliance with hygienic requirements should be carried out during the cold period of the year - on days with the outside air temperature differing from the average temperature of the coldest month of winter by no more than 5 ° C, in the warm period of the year - on days with outside temperature air that differs from the average maximum temperature of the hottest month by no more than 5°C. The frequency of measurements in both periods of the year is determined by the stability of the production process, the functioning of technological and sanitary equipment.

7.2. When choosing areas and measurement times, it is necessary to take into account all factors affecting the microclimate of workplaces (phases of the technological process, functioning of ventilation and heating systems, etc.). Measurements of microclimate indicators should be carried out at least 3 times per shift (at the beginning, middle and end). In case of fluctuations in microclimate parameters associated with technological and other reasons, it is necessary to carry out additional measurements at the highest and lowest values of thermal loads on workers.

7.3. Measurements should be carried out at workplaces. If the workplace consists of several sections of the production premises, then measurements are carried out at each of them.

7.4. If there are sources of local heat release, cooling or moisture release (heated units, windows, doorways, gates, open bathtubs, etc.), measurements should be carried out at each workplace at points minimally and maximally remote from sources of thermal influence.

7.5. In rooms with a high density of workplaces, in the absence of sources of local heat generation, cooling or moisture release, areas for measuring temperature, relative humidity and air velocity should be distributed evenly over the area of the room in accordance with Table. 4.

Table 4

Minimum

number of areas for measuring temperature, relative humidity and air speed

| Room area, | Number of measuring sites |

| Up to 100 | 4 |

| From 100 to 400 | 8 |

| Over 400 | The number of sections is determined by the distance between them, which should not exceed 10 m. |

7.6. When working while sitting, the temperature and speed of air movement should be measured at a height of 0.1 and 1.0 m, and the relative humidity of the air - at a height of 1.0 m from the floor or working platform. When working while standing, the temperature and speed of air movement should be measured at a height of 0.1 and 1.5 m, and the relative humidity of the air - at a height of 1.5 m.

7.7. In the presence of radiant heat sources, thermal exposure at the workplace must be measured from each source, placing the receiver of the device perpendicular to the incident flux. Measurements should be taken at a height of 0.5; 1.0 and 1.5 m from the floor or working platform.

7.8. The temperature of surfaces should be measured in cases where workplaces are no more than two meters away from them. The temperature of each surface is measured in the same way as air temperature in 7.6.

7.9. Temperature and relative humidity in the presence of sources of thermal radiation and air currents in the workplace should be measured using aspiration psychrometers. In the absence of radiant heat and air flows in the measuring areas, the temperature and relative humidity of the air can be measured with psychrometers that are not protected from the effects of thermal radiation and air velocity. Instruments that allow you to separately measure temperature and air humidity can also be used.

7.10. The speed of air movement should be measured with rotational anemometers (vane, cup, etc.). Small values of air velocity (less than 0.5 m/s), especially in the presence of multidirectional flows, can be measured with thermoelectric anemometers, as well as cylindrical and ball catathermometers if they are protected from thermal radiation.

7.11. The temperature of surfaces should be measured with contact devices (such as electric thermometers) or remote ones (pyrometers, etc.).

7.12. The intensity of thermal radiation should be measured with devices that provide a sensor viewing angle close to a hemisphere (at least 160°) and are sensitive in the infrared and visible regions of the spectrum (actinometers, radiometers, etc.).

7.13. The measuring range and permissible error of measuring instruments must comply with the requirements of table. 5.

Table 5

Requirements for measuring instruments

| Indicator name | Range | Maximum deviation |

| Dry bulb air temperature, °C | from -30 to 50 | ±0,2 |

| Air temperature according to wet bulb thermometer, °C | from 0 to 50 | ±0,2 |

| Surface temperature, °C | from 0 to 50 | ±0,5 |

| Relative humidity, % | from 0 to 90 | ±5,0 |

| Air speed, m/s | from 0 to 0.5 | ±0,05 |

| more than 0.5 | ±0,1 | |

| Thermal irradiation intensity, W/m2 | from 10 to 350 | ±5,0 |

| more than 350 | ±500 |

7.14. Based on the results of the study, it is necessary to draw up a protocol, which should reflect general information about the production facility, the placement of technological and sanitary equipment, sources of heat generation, cooling and moisture release, a diagram of the location of areas for measuring microclimate parameters and other data.

7.15. At the conclusion of the protocol, the results of the measurements performed must be assessed for compliance with regulatory requirements.

General provisions and scope

1.1. These Sanitary Rules and Standards (hereinafter referred to as the Sanitary Rules) are intended to prevent the adverse effects of the microclimate of workplaces and industrial premises on the well-being, functional state, performance and health of a person.

1.2. These Sanitary Rules apply to microclimate indicators in workplaces of all types of industrial premises and are mandatory for all enterprises and organizations. References to the obligation to comply with the requirements of these sanitary rules must be included in regulatory and technical documents: standards, building codes and regulations, technical specifications and other regulatory and technical documents regulating the operational characteristics of production facilities, technological, engineering and sanitary equipment that ensure the provision of hygienic microclimate standards.

1.3. In accordance with Articles 9 and 34 of the RSFSR Law “On the Sanitary and Epidemiological Welfare of the Population,” organizations must exercise production control over compliance with the requirements of the Sanitary Rules and carry out preventive measures aimed at preventing the occurrence of diseases of workers in production premises, as well as monitoring compliance with working conditions and rest and implementation of measures for collective and individual protection of workers from the adverse effects of the microclimate.

1.4. Heads of enterprises, organizations and institutions, regardless of their form of ownership and subordination, in order to ensure production control, are obliged to bring workplaces into compliance with the microclimate requirements provided for by these Sanitary Rules.

1.5. State sanitary and epidemiological supervision and control over the implementation of these Sanitary Rules is carried out by bodies and institutions of the State Sanitary and Epidemiological Service of the Russian Federation, and departmental sanitary and epidemiological supervision and control is carried out by bodies and institutions of the sanitary and epidemiological profile of the relevant ministries and departments.

1.6. State sanitary and epidemiological supervision over the construction of new and reconstruction of existing production facilities is carried out at the stages of project development and commissioning of facilities, taking into account the nature of the technological process and the compliance of engineering and sanitary equipment with the requirements of these Sanitary Rules and Building Codes “Heating, Ventilation and conditioning".

1.7. Project documentation for the construction and reconstruction of industrial premises must be agreed upon with the bodies and institutions of the State Sanitary and Epidemiological Service of Russia.

1.8. The commissioning of production premises in order to assess the compliance of the hygienic parameters of the microclimate with the requirements of these Sanitary Rules must be carried out with the mandatory participation of representatives of the State Sanitary and Epidemiological Supervision of the Russian Federation.

Requirements for the microclimate and air environment of MO premises

On January 1, 2021, new sanitary rules SP 2.1.3678-20 “Sanitary and epidemiological requirements for the operation of premises, buildings, structures, equipment and transport, as well as the operating conditions of business entities selling goods, performing work or providing services” came into force ", approved by the Resolution of the Chief State Sanitary Doctor of the Russian Federation (hereinafter referred to as SP 2.1.3678-20). In turn, with the entry into force of SP 2.1.3678-20, the previously valid SanPiN 2.1.3.2630-10 “Sanitary and epidemiological requirements for organizations engaged in medical activities”, approved by the Resolution of the Chief State Sanitary Doctor of the Russian Federation dated May 18, 2010, was declared invalid. N 58. Initially, its validity was supposed to be terminated from 01/01/2021, but later its validity was extended until 03/01/2021. Thus, formally, SP 2.1.3678-20 and SanPiN 2.1.3.2630-10 were in effect simultaneously for three months.

A characteristic feature of the new SP 2.1.3678-20 is that this regulatory act has separate sections that impose sanitary requirements on organizations providing various services. Section number IV “Sanitary and epidemiological requirements for the operation of premises, buildings, structures when carrying out activities by business entities providing medical services” is dedicated to medical organizations.

Section II SP 2.1.3678-20 includes general sanitary and epidemiological requirements for all organizations, regardless of their field of activity. Clause 2.4. SP 2.1.3678-20 contains standards regarding the microclimate and air exchange in the premises of any organizations, including the Moscow Region. Thus, this paragraph establishes that the microclimate and air exchange parameters specified by the requirements of hygienic standards are provided in the premises, and the maximum permissible concentrations of pollutants determined by the requirements of hygienic standards are not allowed to be exceeded in the air.

In paragraph 2.6. Section II SP 2.1.3678-20 determines that premises in which equipment is installed that is a source of dust, chemicals, excess heat and moisture must be provided with a local exhaust ventilation system. In this case, an inspection of the technical condition of the ventilation system is carried out before putting a building (premises) into operation or its reconstruction, then 2 years after commissioning, and subsequently at least once every 10 years. When examining the technical condition of ventilation, instrumental measurements of air exhaust volumes should be carried out. Thus, this requirement is mandatory for execution by the Ministry of Defense.

Previously, the basic requirements for the characteristics of the microclimate and the quality of air masses were set out in subsection 6 of section I of SanPiN 2.1.3.2630-10. Currently, in the matter of compliance with sanitary and epidemiological requirements for microclimate and air masses, one should be guided by the requirements of Section IV SP 2.1.3678-20, as well as a number of other regulations, which will be discussed further.

Let us turn to section 7 of SP 158.13330.2014 “Buildings and premises of medical organizations. Design Rules”, where clause 7.2 states that the designed heat supply, heating, ventilation, air conditioning systems must provide standardized parameters of the microclimate and air environment in accordance with current regulatory documents and the instructions of this section.

When designing heat supply, heating, ventilation and hot water supply for food preparation and laundry services in medical organizations, the requirements of SP 30.13330 and the instructions of section 7 of SP 158.13330.2014 should be met. When placing equipment for heating units, heating, ventilation and air conditioning systems, along with taking into account the general requirements for space-planning solutions for medical buildings, it is necessary to comply with regulatory requirements for the protection of medical premises from noise in accordance with SP 51.13330.

Permissible levels of bacterial contamination of the air environment of MO premises are established depending on their functional purpose and cleanliness class. There are four classes of cleanliness of MO premises: these are class A, class B, class C and class D premises.

Class A premises should be understood as especially clean rooms, which include: operating rooms, maternity rooms, aseptic boxes for hematological and burn patients, wards for premature babies, aseptic block of pharmacies, sterilization room (clean half), boxes of bacteriological laboratories.

Class B premises are clean rooms, which include treatment rooms, dressing rooms, preoperative rooms, intensive care wards and rooms, children's wards, breast milk collection and pasteurization rooms, assistant and packaging pharmacies, bacteriological and clinical laboratories intended for research.

Surgical wards, corridors adjacent to operating rooms, maternity wards, examination rooms, boxes and wards of infectious diseases departments, residents' rooms, clean linen storage rooms are conditionally clean rooms and are codified as class B premises.

Class D premises include corridors and premises of administrative buildings, staircases of medical and diagnostic buildings, sanitary rooms, toilets, premises for temporary storage of dirty linen and temporary storage of waste.

For class G premises, the level of bacterial contamination is not standardized.

In premises of classes A and B, there should be no Staphylococcus aureus in the air. In premises of classes B and D, Staphylococcus aureus is not standardized.

In turn, in the new SP 2.1.3678-20 it is indicated in clause 4.5.6. Section IV that in rooms of cleanliness classes A and B there should be no Staphylococcus aureus in the air. In rooms of cleanliness classes B and D, Staphylococcus aureus is not standardized.

According to clause 4.5.7. SP 2.1.3678-20 operation of ventilation systems must prevent the flow of air masses from rooms of cleanliness class G to rooms of cleanliness classes B, B and A, from rooms of cleanliness class B to rooms of cleanliness classes B and A, from rooms of cleanliness class B to premises of cleanliness class A.

According to the medical design specifications for operating rooms, wards for burn patients and other immunocompromised patients in medical organizations under construction and reconstruction, it is recommended to supply air from above with a unidirectional air flow to the area of the operating table (bed). Clause 7.2.3.25 of SP 158.13330.2014 states that air should be supplied, as a rule, to the upper zone of the room. Air should be supplied to class A rooms through a laminar air distributor, and to class B rooms through ceiling air distributors.

This paragraph also establishes a requirement for air removal, namely air removal is provided for:

- from operating rooms, small operating rooms, anesthesia rooms, resuscitation rooms, and labor zones from two zones: 40% - from the upper zone (10 cm from the ceiling to the top of the grille) and 60% - from the lower zone (60 cm from the floor to the bottom of the grille);

- from barozals and cryogenic storage facilities - only from the lower zone;

- from procedural X-ray diagnostics, radionuclide diagnostics and radiation therapy, from medical gas rooms - 50% each from the upper and lower zones;

- from rooms for working with open radionuclides - 65% from the upper and 35% from the lower zone;

- from the premises for keeping laboratory SPF animals - 35% - from the upper zone and 65% - from the lower zone.

Air removal is provided from the upper zone, except for operating rooms, anesthesia, resuscitation, labor and X-ray procedures, in which air is removed from two zones: 40% from the upper zone and 60% from the lower zone (60 cm from the floor).

The specified legal norm recommends removing air from the remaining rooms from the upper zone.

In turn, clause 7.2.3.27 of SP 158.13330.2014 establishes that in operating units, air movement must be organized from operating rooms to adjacent rooms (preoperative, anesthesia, etc.), and from these rooms to the corridor. In the corridors of operating units, a supply and exhaust ventilation device is required.

The norms of SP 158.13330.2014 oblige, in order to ensure standardized temperature and air humidity in rooms of cleanliness classes A and B, to provide air conditioning using systems and equipment permitted for these purposes in the prescribed manner. According to clause 7.2.3.17 SP 158.13330.2014, air conditioning should be provided in:

- operating rooms;

- anesthesia;

- resuscitation;

- in intensive care wards, maternity wards, post-operative wards, oncohematological wards, burn wards, for AIDS patients, for newborns, premature babies and infants;

- in other rooms with increased requirements for cleanliness, temperature and humidity.

According to the design assignment, as well as for technical and economic reasons, it is possible to equip other rooms with air conditioning systems, while it is recommended by SP 158.13330.2014 to use radiant ceiling panels to cool rooms in the warm season.

Regarding the question of what the temperature should be in air-conditioned rooms, the standards here indicate the need to be guided by the data in Table K1 of Appendix to SP 158.1330.2014 for the cold and warm periods of the year or according to the technological specifications.

In the new SP 2.1.3678-20, paragraphs 4.5.14-4.5.22 are devoted to the sanitary requirements for the microclimate and air masses in the Moscow Region. Let us consider these requirements in more detail.

According to clause 4.5.14. section IV SP 2.1.3678-20 in existing buildings, structures in the absence of mechanically driven supply and exhaust ventilation in infectious diseases departments, natural ventilation must be equipped with each box and boxed ward equipped with air disinfection devices that ensure the effectiveness of inactivation of microorganisms by at least 95 % at the exit.

If it is revealed that there are patients with infectious (parasitic) diseases in the municipality, which can lead to emergencies in the field of sanitary and epidemiological well-being of the population and require urgent sanitary and protective measures, then such patients are isolated in boxes with a mechanical ventilation system.

In all rooms (except for rooms of cleanliness class A), regardless of the presence of forced ventilation systems, natural ventilation must be provided through vents, transoms or openings in window sashes.

In the absence of natural ventilation due to the design features of the building, the supply and exhaust ventilation system must ensure the supply of a sufficient volume of outside air, ensure the proper frequency of air exchange and cleanliness of the air environment in accordance with hygienic standards (clause 4.5.15 of section IV SP 2.1.3678 -20).

In buildings and premises of the Ministry of Defense with a total area of no more than 500 m2 in rooms of cleanliness classes B and C (except for X-ray rooms, computer and magnetic resonance imaging rooms), in the absence of supply and exhaust ventilation systems, ventilation is carried out naturally.

The mandatory requirement is the requirement established by clause 4.5.17. Section IV SP 2.1.3678-20, which obliges the intake of outside air for ventilation and air conditioning systems from a clean area at a height of at least 2 meters from the ground surface, while the outside air itself supplied by air supply units must be cleaned with coarse and fine filters .

In turn, the exhaust air emission should be organized 0.7 m above the roof, while the air emission onto the facade of the building should be after cleaning with filters for the appropriate purpose (clause 4.5.18 of section IV SP 2.1.3678-20).

Air supplied to rooms of cleanliness classes A and B must be subjected to cleaning and disinfection with filters or other devices that ensure the efficiency of cleaning and disinfection of air at the outlet of the installation is at least 99% for rooms of cleanliness class A and 95% for rooms purity class B or filtration efficiency corresponding to high efficiency filters. High efficiency filters must be replaced at least once every 6 months, unless otherwise provided in the operating instructions (clause 4.5.19 of section IV SP 2.1.3678-20).

At the entrance to the ward section, operating unit, resuscitation and intensive care section, a gateway must be installed.

If split systems are used in doctors' offices, as well as in wards, administrative and auxiliary rooms, it is necessary to clean and disinfect filters and heat exchanger chambers in accordance with the manufacturer's technical documentation, but at least once every 3 months (clause 4.5.22 Section IV SP 2.1.3678-20).

The air exchange itself in the wards and departments, in accordance with clause 4.5.18 of Section IV SP 2.1.3678-20, must be organized in such a way as to prevent the flow of air between ward departments, between wards, and between adjacent floors. If the ward contains a toilet, then in this case the design of the ventilation systems should exclude the possibility of air flow from the toilet into the ward.

As part of production control, monitoring of microclimate parameters and indicators of microbial contamination of the air environment is organized at a frequency of at least once every 6 months and contamination of the air with chemicals at least once a year.

Normative references

2.1. Law of the RSFSR “On the sanitary and epidemiological welfare of the population.”

2.2. Regulations on the State Sanitary and Epidemiological Service of the Russian Federation and Regulations on the State Sanitary and Epidemiological Standards, approved by Decree of the Government of the Russian Federation of June 5, 1994, No. 625.

2.3. Guidelines “General requirements for the construction, presentation and execution of sanitary-hygienic and epidemiological normative and methodological documents” dated February 9, 1994 R 1.1.004-94.

Terms and Definitions

3.1. Industrial premises

— closed spaces in specially designed buildings and structures in which people’s labor activities are carried out constantly (in shifts) or periodically (during the working day).

3.2. Workplace

- an area of the premises in which labor activity is carried out during a work shift or part of it. A workplace can be several areas of a production facility. If these areas are located throughout the room, then the entire area of the room is considered a workplace.

3.3. Cold season

- a period of the year characterized by an average daily outdoor temperature of +10 °C and below.

3.4. Warm period of the year

- a period of the year characterized by an average daily outdoor temperature above +10 °C.

3.5. Average daily outside air temperature

- the average value of outdoor air temperature measured at certain hours of the day at regular intervals. It is taken according to the meteorological service.

3.6. Dividing work into categories

is carried out on the basis of the intensity of the body’s total energy expenditure in kcal/h (W). Characteristics of individual categories of work (Ia, Ib, IIa, IIb, III) are presented in the Appendix.

3.7. Thermal load of the environment (THL)

- the combined effect on the human body of microclimate parameters (temperature, humidity, air speed, thermal radiation), expressed as a single-digit indicator in °C.

Requirements for heating and ventilation MO

With regard to the sanitary requirements for heating systems in the Moscow Region, it should be noted that in the new SP 2.1.3678-20 there are practically no standards regulating these requirements.

So, only in paragraph 4.5.1. Section IV SP 2.1.3678-20 specifies the requirement that heating devices must have a surface that prevents dust adsorption and is resistant to cleaning and disinfecting solutions. When constructing fences for heating devices, free access for routine operation and cleaning must be ensured.

Thus, there are actually no special standards regarding sanitary requirements for heating systems specifically in the Moscow Region in the new set of rules, so in this matter it is necessary to refer to the standards of other legal acts. So, in paragraphs 7.2.1.1-7.2.1.2. SP 158.1330.2014 establishes that heat supply reliability organizations are divided into two categories:

I - buildings with permanent stay of patients: hospitals, maternity hospitals, dispensaries and other buildings with a hospital;

II - other buildings.

When designing heat supply systems for category I heat consumers, two heat inputs should be provided from independent sources, or from looped heating mains with redundant heat supply from heating networks. If there is one input, it is allowed to provide a backup boiler room on the site of the medical organization, subject to sanitary gaps to the buildings.

Clause 7.2.1.9 of SP 158.1330.2014 establishes that heat supply systems for buildings of medical organizations must be connected to heating networks through a heating point. Laying superheated water pipelines from the heating point to the premises for ventilation equipment of fresh air ventilation systems along operated premises and evacuation routes is prohibited. The calculated as well as permissible air temperature in the premises is taken in accordance with Table K.1 of Appendix to SP 158.1330.2014 and the requirements of SP 60.13330.

SP 158.1330.2014 also defines regulatory requirements for the placement of heating devices, according to which heating devices should be placed, as a rule, under light openings - in places accessible for inspection, repair and cleaning, at a distance of at least 100 mm from the level of the finished floor and not less than 60 mm from the wall surface. When justified, it is allowed to place the missing heating surface on internal fences adjacent to the external walls. Heating panel radiators in hygienic design (steel radiators with a smooth surface allowing easy cleaning) are used in rooms belonging to cleanliness classes A, B, C and D (clause 7.2.2.4 - 7.2.2.4 SP 158.13330.2014).

As for supply and exhaust ventilation systems, all municipalities without exception must be equipped with them. This system can be mechanical and/or natural driven. In general, the requirements for ventilation systems that were presented within the framework of the current SanPiN 2.1.3.2630-10 formed the basis for the requirements for ventilation systems in the Moscow Region in accordance with the new SP 2.1.3678-20; for the most part, these requirements are duplicated. Let us consider in more detail what requirements are currently imposed on ventilation systems in the Moscow Region.

According to clause 4.5.2. Section IV SP 2.1.3678-20 once a year must be checked for operational efficiency, as well as cleaning and disinfection of mechanical supply and exhaust ventilation and air conditioning systems.

In aseptic rooms, the air flow should prevail over the exhaust hood. In rooms with an infectious profile, the exhaust should prevail over the air flow.

If a MO is located in a residential building, then the ventilation system in such a MO should be separate from the ventilation of an apartment building. The MoD should also ensure that ventilation systems operate in such a way that the requirements for vibration and noise levels are met, since in practice it often happens that these requirements are not met, and the operation of the ventilation system is allowed to exceed the standards established for noise and vibration levels.

Appendix 3 to SP 2.1.3678-20 defines the limit values for the content of the total number of microorganisms in 1 m3, taking into account temperature and air exchange rate. According to clause 4.5.5. Section IV SP 2.1.3678-20, the air in MO premises must correspond to the limit value of the total number of microorganisms in 1 m3, taking into account the temperature and air exchange rate in accordance with the specified appendix.

Clause 4.5.23. Section IV SP 2.1.3678-20 obliges to organize exhaust ventilation with mechanical impulse without organizing an organized influx from the premises:

- showers,

- sanitary facilities,

- rooms for dirty linen,

- temporary storage of waste and storerooms for storing disinfectants, reagents and other substances with a pungent odor.

The equipment of supply ventilation systems serving rooms of cleanliness class A is located in a separate room (ventilation chamber), and the equipment of other supply and exhaust ventilation systems must be placed in a separate room (ventilation chamber) or in a climate-controlled room on the roof of the building. Duct ventilation equipment is located behind a false ceiling, in corridors and rooms without permanent occupancy (clause 4.5.24 of section IV SP 2.1.3678-20).

All rooms of cleanliness class A must have hidden installation of pipelines and fittings. In other rooms, air ducts are placed in closed ducts (clause 4.5.28, section IV SP 2.1.3678-20). According to clause 4.3.1. Section IV SP 2.1.3678-20 in ventilation chambers, floors must have a coating that does not generate dust during operation.

For rooms in which manipulations are carried out that violate the integrity of the skin or mucous membranes, the use of ultraviolet bactericidal irradiators or other devices and equipment for air disinfection is mandatory.

As for air ducts, according to paragraphs 4.5.26-4.5.27 of Section IV SP 2.1.3678-20, the supply ventilation and air conditioning system must have an internal non-sorbing surface that prevents the removal of particles of air duct material or protective coatings into the premises. Air ducts, air distribution and air intake grilles, ventilation chambers, ventilation units, heat exchangers must be kept clean and free from mechanical damage, signs of corrosion, or leaks. The use of ventilation chambers for purposes other than their intended purpose is prohibited. Cleaning of ventilation chambers should be carried out at least once a month, and air intake shafts - at least once every 6 months. Maintenance, cleaning and disinfection of ventilation systems is carried out at least once a year.

It is imperative to ensure protection of attic and basement vents from the penetration of rodents, birds and synanthropic insects (clause 4.5.29 of section IV SP 2.1.3678-20).

To fulfill all the established requirements for ventilation systems of the Moscow Region, it is necessary to be guided by the standards of SP 158.1330.2014.

According to clause 7.2.3.10 of SP 158.1330.2014, departments (diagnostic, treatment (including ward), outpatient clinics, administrative and auxiliary units) with the same sanitary and hygienic requirements and operating hours, including those located on different floors, can be equipped with one centralized supply and exhaust ventilation and air conditioning system. If such a central ventilation system is organized in the Moscow Region, then it is necessary to fulfill the requirement set out in clause 4.5.31. section IV SP 2.1.3678-20, which states that in the presence of centralized air conditioning and humidification systems in order to prevent nosocomial legionellosis, microbiological monitoring of these systems for the presence of legionella is carried out 2 times a year. At the same time, split systems and air conditioning units without air humidification are not subject to control for legionella.

Any mechanical supply and exhaust ventilation system in the Moscow Region must be certified. Operation (maintenance) of mechanical supply and exhaust ventilation and air conditioning is carried out by the responsible person of the organization or another specialized organization. Once a year, performance checks, routine repairs (if necessary), as well as cleaning and disinfection of mechanical supply and exhaust ventilation and air conditioning systems are carried out. The design and operation of ventilation systems must prevent the flow of air masses from “dirty” rooms to “clean” ones. This requirement is important, since the lack of necessary documentation for the ventilation system or the lack of control during its operation may become a reason for bringing the Ministry of Defense or its officials to administrative liability.

General requirements and microclimate indicators

4.1. Sanitary rules establish hygienic requirements for the microclimate indicators of workplaces in industrial premises, taking into account the intensity of energy expenditure of workers, the time of work, periods of the year and contain requirements for methods of measuring and monitoring microclimatic conditions.

4.2. Microclimate indicators must ensure the preservation of the thermal balance of a person with the environment and the maintenance of an optimal or acceptable thermal state of the body.

4.3. Indicators characterizing the microclimate in production premises are:

• air temperature;

• surface temperature*;

• relative humidity;

• air speed;

• intensity of thermal radiation.

___________

* The temperature of the surfaces of enclosing structures (walls, ceilings, floors), devices (screens, etc.), as well as technological equipment or enclosing devices is taken into account.

Appendix 1 (for reference)

1. Categories of work are delimited based on the intensity of the body’s energy expenditure in kcal/h (W).

2. Category Ia includes work with an intensity of energy consumption of up to 120 kcal/h (up to 139 W), performed while sitting and accompanied by minor physical stress (a number of professions in precision instrumentation and mechanical engineering enterprises, in watchmaking, sewing production, in the field of management, etc. .P.).

3. Category Ib includes work with an energy intensity of 121 - 150 kcal/h (140 - 174 W), performed while sitting, standing or associated with walking and accompanied by some physical stress (a number of professions in the printing industry, communications enterprises, controllers, foremen in various types of production, etc.).

4. Category IIa includes work with an energy intensity of 151 - 200 kcal/h (175 - 232 W), associated with constant walking, moving small (up to 1 kg) products or objects in a standing or sitting position and requiring a certain physical exertion (a number professions in mechanical assembly shops of machine-building enterprises, in spinning and weaving production, etc.).

5. Category IIb includes work with an energy intensity of 201 - 250 kcal/h (233 - 290 W), associated with walking, moving and carrying weights up to 10 kg and accompanied by moderate physical stress (a number of professions in mechanized foundries, rolling, forging, thermal, welding shops of machine-building and metallurgical enterprises, etc.).

6. Category III includes work with an energy intensity of more than 250 kcal/h (more than 290 W), associated with constant movement, moving and carrying significant (over 10 kg) weights and requiring great physical effort (a number of professions in forge shops with hand forging , foundries with manual filling and pouring of flasks of machine-building and metallurgical enterprises, etc.).

Optimal microclimate conditions

5.1. Optimal microclimatic conditions are established according to the criteria of the optimal thermal and functional state of a person. They provide a general and local feeling of thermal comfort during an 8-hour work shift with minimal stress on the thermoregulation mechanisms, do not cause deviations in health, create the prerequisites for a high level of performance and are preferred in the workplace.

5.2. Optimal values of microclimate indicators must be observed at workplaces of industrial premises where operator-type work associated with nervous and emotional stress is performed (in cabins, at consoles and control stations for technological processes, in computer rooms, etc.). The list of other workplaces and types of work in which optimal microclimate values must be ensured is determined by the Sanitary Rules for individual industries and other documents agreed upon with the State Sanitary and Epidemiological Supervision authorities in the prescribed manner.

5.3. The optimal microclimate parameters at workplaces should correspond to the values given in table. , in relation to the performance of work of various categories in the cold and warm periods of the year.

5.4. Changes in air temperature in height and horizontally, as well as changes in air temperature during a shift, while ensuring optimal microclimate values in the workplace, should not exceed 2 °C and go beyond the values specified in the table. for certain categories of work.

Table 1

Optimal values of microclimate indicators in industrial workplaces

| Period of the year | Category of work by energy consumption level, W | Air temperature, °C | Surface temperature, °C | Relative humidity, % | Air speed, m/s |

| Cold | Ia (up to 139) | 22 — 24 | 21 — 25 | 60 — 40 | 0,1 |

| Ib (140 - 174) | 21 — 23 | 20 — 24 | 60 — 40 | 0,1 | |

| IIa (175 - 232) | 19 — 21 | 18 — 22 | 60 — 40 | 0,2 | |

| IIb (233 - 290) | 17 — 19 | 16 — 20 | 60 — 40 | 0,2 | |

| III (over 290) | 16 — 18 | 15 — 19 | 60 — 40 | 0,3 | |

| Warm | Ia (up to 139) | 23 — 25 | 22 — 26 | 60 — 40 | 0,1 |

| Ib (140 - 174) | 22 — 24 | 21 — 25 | 60 — 40 | 0,1 | |

| IIa (175 - 232) | 20 — 22 | 19 — 23 | 60 — 40 | 0,2 | |

| IIb (233 - 290) | 19 — 21 | 18 — 22 | 60 — 40 | 0,2 | |

| III (over 290) | 18 — 20 | 17 — 21 | 60 — 40 | 0,3 |

Requirements for ventilation systems and air environment in certain premises and types of medical facilities

The new SP 2.1.3678-20 establishes standards governing the requirements for ventilation systems and the air environment for certain categories of Ministry of Defense premises that have a special profile.

So, clause 4.11.1. Section IV SP 2.1.3678-20 establishes that such MO premises as operating units must be located in rooms equipped with an autonomous supply and exhaust ventilation and air conditioning system that ensures standardized microclimate parameters and air cleanliness.

In hypoxic therapy rooms, anti-noise measures from compressor operation and natural ventilation should be implemented. There must be a separate room for washing and disinfecting masks and hoses. Between sessions there is a break for ventilation. After the end of the work shift, cleaning should be carried out using detergents and disinfectants, as well as air disinfection (4.6.13, Section IV SP 2.1.3678-20).

In accordance with clause 4.20.1. section IV SP 2.1.3678-20, pathological departments that carry out pathological autopsies, and forensic medical examination departments that examine corpses, are located in separate buildings or as part of other buildings of medical organizations in the presence of planning isolation and autonomous ventilation systems.

In premises subject to aseptic conditions, clause 4.26.16. Section IV SP 2.1.3678-20 obliges the hidden installation of air ducts, pipelines, and fittings.

A number of standards in the new SP 2.1.3678-20 are devoted to ventilation systems in dental hospitals. So, clause 4.26.12. Section IV SP 2.1.3678-20 establishes the requirement that in dental medical organizations with a total area of no more than 500 sq. m, in rooms of cleanliness classes B and C (except for operating rooms, X-ray rooms, computer and magnetic resonance imaging rooms), ventilation of the premises is carried out through opening transoms or exhaust ventilation without mechanical impulse.

Norms clause 4.26.13. Section IV SP 2.1.3678-20 allows in the premises of a dental (dental) laboratory to combine local suction and general exhaust ventilation into one exhaust system within the premises of the laboratories or in the premises of the ventilation chamber. A device for general exchange supply ventilation for laboratory premises and other premises of a dental medical organization, while the supply of fresh air to the laboratory premises must be organized through a separate air duct passing from the ventilation chamber, with a check valve installed on it within the ventilation chamber.

The technological equipment of the dental (dental) laboratory, which includes sections for cleaning the exhaust air from this equipment, as well as closed-circuit equipment, does not require additional local suction. In dental laboratories there should be local suction from the workplaces of dental technicians, grinding motors, in the foundry above the furnace, in the soldering room, above heating devices and work tables in the room for polymerization of materials. The air released into the atmosphere must be purified in accordance with the technological characteristics of the equipment and materials. Local suction systems must be structurally independent from the general exhaust ventilation systems of dental medical organizations (clauses 4.26.14.-4.26.15 of Section IV SP 2.1.3678-20).

Previously in SanPin 2.1.3.2630-10.27.4. a separate section V was included, which was devoted to the sanitary requirements for first-aid posts and outpatient clinics, in particular for ventilation, heating and microclimate systems. In the current SP 2.1.3678-20 there is only one paragraph 4.27.4., which establishes sanitary requirements for first aid stations and outpatient clinics, in particular, it states that the buildings of paramedic obstetric stations and outpatient clinics are equipped with natural ventilation. Therefore, in this matter, one should focus on the design and construction standards of residential and public buildings and try to ensure optimal parameters of the microclimate and air environment in the premises of the first aid station or outpatient clinic, incl. according to microbiological indicators.