If a person takes a new job, he should definitely be familiarized with safety issues.

Especially for these issues, each enterprise has a complex called “Labor Safety”. It is thanks to the established requirements and their compliance that a high level of security is achieved in the organization. Only when all workers comply with the requirements can emergency situations be avoided. When getting acquainted with a new position, a potential employee must undergo induction training. The procedure ends with testing the acquired knowledge. In this way, those in charge make sure that the person understands what was taught.

Free legal consultation by phone:

8

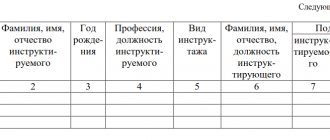

There is a possibility that after a certain time spent in the workplace, the acquired knowledge will be forgotten. Therefore, in addition to introductory training, there is also repeated instruction on labor protection. It is needed not only for testing, but also for gaining new knowledge. It should be borne in mind that legislative and local acts tend to change over time.

Initial training at the workplace is conducted with whom?

In accordance with clause 8.7 of GOST 12.0.004-2015, initial training at the workplace is carried out before the start of independent work of the instructed persons:

- with all newly hired persons, including for short-term, seasonal and other temporary work, in their free time from the main job (part-time workers), as well as at home (homeworkers) using materials, tools and mechanisms provided by the employer or purchased them at their own expense;

- with workers transferred in accordance with the established procedure from another department, or with workers who are entrusted with performing work that is new to them;

- with personnel from other organizations sent to work for the training organizer;

- with the personnel of contractors (subcontractors) performing work on the territory and facilities controlled by the training organizer;

- with students of educational institutions of appropriate levels undergoing practical training (practical classes), and with other persons participating in the production activities of the enterprise that organizes the training.

Approval procedure

After agreeing on the program, the head of the structural unit submits it for approval by the manager.

A special order is issued for the enterprise, approving it. The developed document is attached to the order as an appendix.

The order approving the program does not have a specific form. However, there are main points recommended for inclusion in the document:

- The document header contains:

- Company name;

- publication date;

- document's name;

- order number;

- what is the order about?

- The text of the order itself contains the fact of approval of the program, who is responsible for compliance with its provisions and familiarization with the order.

- The final part contains the manager’s visa and a list of attached documentation (Appendix No. 1).

How to compose?

There is no special form for the retraining program approved by law.

But the most important points of the document can be found in GOST 12.0.004-90.

Approximate content of the program:

The first part of the document contains the following data:

- production of a product by the company as a whole, by the workshop separately (technological process of product manufacturing);

- about equipment;

- a list of harmful and dangerous factors of work activity and their impact on the human body;

- protective equipment;

- features of equipment operation;

- basic methods of protection and conditions for their use;

- basic rules for preparing and creating a place of work;

- safe use of work equipment during the work process;

- conditions for protection against injury from electricity.

The second part of the document describes the preparatory stage for work and describes:

- information on special clothing and footwear (including protective equipment);

- rules for checking and preparing the equipment and machinery used;

- security regarding the work process.

- training for safe movement of workers which includes:

- possible movement diagram;

- location of emergency exits and prohibited areas;

- marked places of transport and lifting mechanisms.

- emergency positions appearing during the work process with the following symbols:

- reasons for emergencies;

- ways to prevent them;

- actions of personnel in critical circumstances;

- locations of protective equipment and rules for their use;

- first aid kit storage areas;

- devices for communication needs;

- employees who can be contacted if a problem arises.

It is allowed to include additional items in the retraining program if the manager considers it necessary.

All employees are obliged to undergo training according to a pre-developed program.

Due to the specifics of the employee’s work activity, depending on the place of work in production, the instructions may be different.

All production personnel are required to thoroughly review the program information provided to them.

Initial briefing at the workplace: who conducts it?

Initial briefing at the workplace is carried out by the head of the department or the immediate supervisor (producer) of the work (foreman, foreman, teacher, etc.), who has undergone training in labor protection in the prescribed manner and tested knowledge of labor protection requirements as a labor protection instructor.

Initial on-the-job training for personnel of contracting (subcontracting) organizations performing work on territories and facilities controlled by the enterprise that organizes the training is carried out by the immediate supervisor (producer) of the work - a representative of the contracting (subcontracting) organization together with the head of the department or with the person responsible for the contract work. at workplaces (in the work area, territory) of this unit. The procedure for the safe performance of these works, including the procedure for instructing workers, can be drawn up in a separate document, which is an integral part of the contract for the performance of contract (subcontract) work (rendering services).

PROGRAM CONTENT

| No. | Topic name | Watch |

| 1 | General information about the specifics and features of the organization. Walk-through of the facility indicating the installation locations of fire extinguishing equipment and emergency exits | 0,5 |

| 2 | Duties and responsibilities of employees for compliance with fire safety requirements | 0,5 |

| 3 | Familiarization with the established fire safety regime in the organization, the order establishing the fire safety regime, fire safety instructions | 1 |

| 4 | General measures for fire prevention and fire extinguishing: actions in case of fire or fire, reporting a fire to the fire department, to the immediate supervisor, techniques and means of extinguishing a fire or fire | 0,5 |

| 5 | Practical training of actions in case of fire and testing of knowledge of fire extinguishing equipment and fire protection systems | 2 |

| Total: | 4,5 |

According to which local act is initial training carried out at the workplace?

In accordance with clause 8.7 of GOST 12.0.004-2015, initial training at the workplace is carried out by:

- or according to programs (Appendix B, program B.2) developed and approved by the training organizer in the prescribed manner in accordance with the requirements of legislative and other regulatory legal acts on labor protection, local regulations, instructions on labor protection in the workplace and on safe implementation works, other technical and operational documentation necessary to ensure safety,

- or directly according to instructions on labor protection and (or) safe performance of work at a given workplace,

- according to other local regulations and documents necessary for instruction.

According to the new GOST, initial training in the workplace can be carried out according to an approved program of initial training in the workplace or according to instructions on labor protection in the workplace, and this mechanism must be enshrined in the local regulatory act of the organization.

I believe that it is important to maintain continuity with GOST 12.0.004-90 and carry out initial training at the workplace according to the approved Program for Initial Training at the Workplace, in which we indicate which labor safety instructions we provide for the given position of the employee.

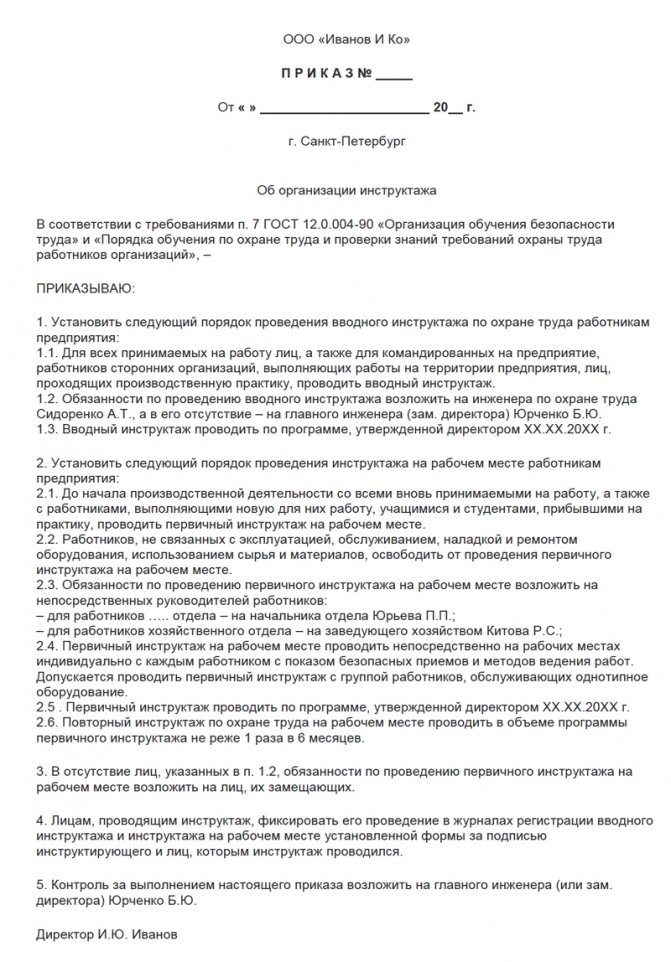

Sample order for repeated training on labor protection

This order is issued simultaneously for all types of training related to occupational safety. It does not have a standard form, but the company’s company sheet can be used for it. First you need to enter the date and order number. The text itself indicates a list of persons for whom this procedure is established and for whom exceptions are made. The regularity of repeated training must be mentioned in the content of the administrative document. It is important to use an order to select a responsible person who will familiarize new and existing employees with the existing rules.

Questions recommended for inclusion in the Initial Workplace Training Program

GOST 12.0.004-90 Appendix No. 5 recommended including ten questions in the initial workplace training program. GOST 12.0.004-2015 recommends including five questions. The analysis of the proposed issues is aimed at strengthening preventive work with workers on labor protection.

GOST 12.0.004-2015 recommends that the Initial Instruction Program at the workplace include the following questions:

1. General information about the employee’s working conditions: the technological process, equipment and production environment at the employee’s workplace, the nature of his work process (tension and severity):

- general information about the technological process and products manufactured by the division;

- general familiarity with the equipment located at the workplace, in the work area and within the territory and premises controlled by the unit;

- dangerous and harmful production factors present in the workplace and the risks of their impact on the human body;

- collective protection means installed on the equipment (safety, braking devices and fences, locking systems, alarms, etc.);

- purpose, design and rules for using personal protective equipment (PPE) required in the workplace;

- requirements for the safe organization and maintenance of a clean and tidy workplace;

- safety requirements for operation and maintenance (repair) of equipment located in the workplace;

- safety requirements for the prevention of electrical injuries.

2. Procedure for preparing for work:

- requirements for workwear, safety footwear and personal protective equipment;

- checking the serviceability of equipment, starting devices, tools, devices, interlocks, grounding and other protective equipment;

- safe techniques and methods when performing work.

3. Scheme for the safe movement of an employee within the territory of a unit or organization:

- passages provided for movement;

- emergency exits, restricted areas;

- intra-shop transport and lifting equipment, locations and safety requirements when carrying out lifting operations.

4. Emergency situations that may arise in the workplace:

- characteristic causes of accidents, explosions, fires, cases of industrial injuries and acute poisoning;

- employee actions in the event of an emergency, industrial injury, acute poisoning;

- locations of emergency protection and fire extinguishing equipment, rules for their use;

- location of first aid equipment for the victim, first aid kits, rules for their use;

- telephone service locations, telephone numbers;

- the employee’s actions in the event of a dangerous situation that threatens the life and health of others, and in the event of an accident at work;

- the procedure for an employee to report to representatives of the employer about an accident or acute poisoning that has occurred to him.

5. Familiarization with all instructions on the workplace and labor protection by profession (in accordance with the list of professions developed by the employer for each workplace, indicating the numbers of instructions required for instruction).

The initial training program (Appendix B) is only a base, which must be supplemented with information about the dangerous or harmful production factors present in a given workplace and other information that an employee needs to know to work safely.

In accordance with the old GOST 12.0.004-90 clause 7.2.2. “Initial training in the workplace is carried out according to programs developed and approved by the heads of production and structural divisions of the enterprise, educational institution for certain professions or types of work, taking into account the requirements of safety standards, relevant rules, norms and instructions on labor protection, production instructions and other technical documentation . The programs are coordinated with the labor protection department (bureau, engineer) and the trade union committee of the unit or enterprise.”

GOST 12.0.004-2015 does not provide for coordination of the Initial Instruction Program at the workplace with the labor protection department and the trade union committee of the enterprise.

You can download the Initial Workplace Instruction Program in the “Practical Materials” section

In connection with GOST 12.0.004-2015 “System of occupational safety standards. Organization of occupational safety training. General provisions" organizations are required to make changes to the Initial Instruction Program at the workplace.

PROGRAM SUMMARY

- General information about the specifics and features of the organization.

The office of XXX LLC is located on the ____ floor in the ____-storey building. Evacuation plans are located on all floors of the building.

Up to _____ people can be in the office premises at a time.

Access time to office premises: from _______ to _______

located in a 2-story building. Explosion and fire hazard category – B. Operating hours – 24 hours a day.

Employees of the main professions of XXX LLC carry out work on the 1st floor of the plant building.

The office and factory fire safety system includes the following technical means:

- primary fire extinguishing agents in sufficient quantities (powder fire extinguishers);

- automatic fire alarm with fire warning system;

- smoke removal system;

- emergency lighting of the building;

- internal fire water supply (fire hydrants and hoses).

Evacuation routes and exits from buildings are made in accordance with established standards. All evacuation routes are equipped with evacuation signs, and emergency exits are equipped with illuminated “EXIT” signs.

- Duties and responsibilities of employees for compliance with fire safety requirements.

The employee’s responsibility for compliance with fire safety requirements at XXX LLC is established by the order on the fire safety regime, instructions on fire safety and job descriptions.

If the requirements of the established fire safety regime are not met, the following disciplinary measures may be applied to the employee: reprimand, reprimand, dismissal.

Responsibility for non-compliance with the requirements of the fire safety regime established by the state is reflected in the Code of the Russian Federation on Administrative Offenses (Article 20.4) and the Criminal Code of the Russian Federation (Article 219).

- Familiarization with the established fire safety regime in the organization, the order establishing the fire safety regime, fire safety instructions

The fire safety regime in XXX LLC is established by order and instructions on fire safety. The order and instructions are updated as necessary due to changes in responsible persons or changes in fire safety legislation.

Basic fire safety requirements:

- Smoking and the use of open flames are prohibited on the territory and in premises, except in areas designated for smoking;

- It is prohibited to leave containers with flammable and combustible liquids and combustible gases on the territory and in the premises;

- It is prohibited to store and use flammable and combustible liquids, gunpowder, explosives, pyrotechnic products, cylinders with flammable gases, goods in aerosol packaging, celluloid and other fire-explosive substances and materials in attics, basements and basements;

- It is prohibited to use attics, technical floors, ventilation chambers and other technical premises for organizing production areas, workshops, as well as for storing products, equipment, furniture and other items;

- It is prohibited to remove the doors of evacuation exits from floor corridors and halls provided for in the design documentation, or other doors that prevent the spread of fire hazards along evacuation routes;

- It is prohibited to clutter doors, transitions to adjacent sections and exits to external evacuation staircases and escape routes with furniture, equipment and other objects;

- It is prohibited to fix self-closing doors of staircases, corridors, and halls in the open position, or to remove them;

- It is prohibited to clean premises and wash clothes using gasoline, kerosene and other flammable and combustible liquids, as well as to warm frozen pipes with blowtorches and other methods using open fire;

- It is prohibited to arrange storage rooms and other utility rooms in stairwells and floor corridors, as well as to store things, furniture and other flammable materials under flights of stairs and on landings;

- Special clothing for persons working with oils, varnishes, paints and other flammable and combustible liquids should be stored hanging in metal cabinets;

- Locks on emergency exit doors must allow them to be opened freely from the inside without a key;

- When working with flammable and fire-explosive substances and materials, comply with the requirements of markings and warning notices indicated on the packaging or in accompanying documents;

- The combined use (unless provided for by the technological regulations), storage and transportation of substances and materials that, when interacting with each other, are capable of igniting, exploding or forming flammable and toxic gases (mixtures) is prohibited;

- Carpets, carpet runners and other floor coverings in rooms with large numbers of people and on escape routes must be securely fastened to the floor;

- Workplaces should be cleaned using methods that prevent dust agitation and the formation of explosive dust-air mixtures;

- At the end of working hours, it is prohibited to leave electrical installations, household electrical appliances and computers un-energized in rooms where there is no staff on duty, with the exception of emergency lighting, fire protection systems, as well as other electrical installations and electrical devices, if this is due to their functional purpose and (or) provided for by the requirements of the operating instructions;

- It is prohibited to operate electrical wires and cables with visible insulation damage;

- It is prohibited to use sockets, switches, and other electrical installation products that are damaged;

- It is prohibited to wrap electric lamps and lamps with paper, cloth and other flammable materials, as well as to operate lamps with removed caps (diffusers) provided for by the design of the lamp;

- It is prohibited to use electric irons, electric stoves, electric kettles and other electric heating devices that do not have thermal protection devices, as well as in the absence or malfunction of thermostats provided by the design;

- It is prohibited to use non-standard (homemade) electric heating devices;

- It is prohibited to leave electric heating devices, as well as other household electrical appliances, unattended, connected to the electrical network, including those in standby mode, with the exception of electrical appliances that can and (or) must be in 24-hour operating mode in accordance with the manufacturer’s instructions;

- It is prohibited to place (store) flammable (including flammable) substances and materials in electrical switchboards, near electric motors and starting equipment;

- It is prohibited to leave ventilation chamber doors open;

- Ensure that fire hoses are permanently connected to the fire hydrant and fire nozzle;

- Do not pour flammable or combustible liquids down the drain.

- General measures for fire prevention and fire extinguishing: actions in case of fire or fire, reporting a fire to the fire department, to the immediate supervisor, techniques and means of extinguishing a fire or fire

If a fire or signs of combustion are detected in a building or room (smoke, burning smell, increased air temperature, etc.), the employee must:

- Immediately report the fire to the nearest fire department by phone - 01, 112;

- Immediately notify people about the fire and inform the manager;

- If possible, open all emergency exits and evacuate people from the building;

- If possible, remove the most valuable property and documents from the building;

- When leaving a room or building, turn off the ventilation and close all doors and windows behind you.

- Turn off the power supply.

ATTENTION! A fire is not yet a fire. A fire is an UNCONTROLLED combustion. If it is possible to extinguish the fire with primary means (fire hydrant, fire extinguisher), use it. But, only if you have confident skills in using primary fire extinguishing agents!

In case of fire, people often die not from open fire, but from carbon monoxide poisoning. Carbon monoxide accumulates in the upper levels of the room, therefore, when evacuating, it makes sense to move as low as possible (on all fours, crawling).