Initial briefing on labor protection - introduction

This article contains information that relates to initial instruction on labor protection: a sample list of topics common to many organizations that need to be covered during instruction;

lists of persons who undergo this instruction or who may not undergo it; answers to typical questions that arise for decision-makers. The initial occupational safety training program covers safety provisions that an employee or student will constantly encounter. This instruction is carried out after the introductory briefing, before the immediate start of the activity that the instructee will be engaged in. It is carried out with subordinates one at a time or with a group that will be engaged in the same type of activity.

For whom is initial training on labor protection required?

Primary training on labor protection is necessary for workers:

• large, medium and small companies of all areas of activity, educational, trade institutions, hospitals, offices of companies and firms; • employed by individual entrepreneurs who use hired labor; • working remotely, if the employer provides them with equipment or machinery or recommends its use to perform specific work; • working from home using equipment or materials provided by the employer;

as well as pupils and students:

• who will begin educational, production, and any other practical activities; • before performing each practical task that is new to them during laboratory and practical classes.

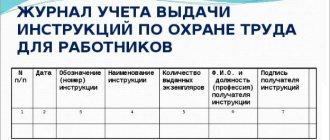

Initial briefings on labor protection, samples of which are kept by those responsible for instructing subordinate employees, are mandatory for:

• workers who move to a new place; • employees who have recently been employed and have undergone induction training; • workers who will work in additional professions (for example, a conveyor operator, if necessary, will replace a repairman). At the same time, instruction alone is not enough - appropriate professional training must be carried out; • seconded, temporarily employed, seasonal workers; • employees of contractors and subcontractors who will perform work simultaneously with the main personnel of the customer or work in areas temporarily transferred to their disposal.

This instruction is read to workers by their direct supervisor. Before this, he must undergo full training in all occupational safety issues raised during the briefing and have a valid occupational safety certificate. This obligation is fixed by order.

Who is undergoing initial training?

Everyone undergoes this training.

Completion of initial training is mandatory for persons starting to perform production tasks for the first time.

These include:

- Employees who recently came to the enterprise;

- Employees of the enterprise who, according to a personal statement, move from one position to another;

- Students or other persons who work under a temporary employment contract;

- Employees whose specific activities require forced transfer to another position. For example, boiler operators are registered in this specialty during the heating season, and in the summer they are transferred to boiler equipment repairmen;

- Other employees who are required to undergo initial training based on their functional responsibilities.

The initial briefing is carried out by the immediate supervisor.

Initial training program on labor protection

Initial instruction on labor protection, a sample of which must be kept by the management of the company's division, is organized exclusively at the workplace. Appendix 5 to GOST 12.0.004-90 offers a list of the main topics that are recommended to be covered during this instruction. It includes:

1. The equipment used, its features, methods of ensuring safety.

2. Overview information about production technology and processes carried out in the department.

3. Circumstances of injuries, accidents that occurred in similar workplaces, their causes, ways to prevent them.

4. Hazards that may be encountered during work: hazardous areas of equipment, possible malfunctions, negative environmental influences, what a worker should do when something goes wrong.

5. Fire and electrical safety, evacuation schemes.

6. Sequence of preparation for work and its completion.

7. Safety rules during the execution of work, requirements for the quality of their execution.

8. Safety rules for various types of work, including dangerous ones, and transportation of goods.

9. Rules for safe behavior in the workplace and tool care.

10. Information about fire extinguishing equipment, electrical protection, alarm systems, personal protective equipment.

11. Tasks that are solved at this workplace, associated features, requirements, factors with a negative effect on the body.

The initial training program on labor protection includes the requirements of occupational safety instructions, internal regulations, and other local regulatory documentation, the requirements of which are mandatory for the employee to comply with. It is developed by the head of the unit, who has undergone occupational safety training appropriate to his position. Next, it needs to be agreed upon by the OT service and approved by the head of the organization.

When conducting initial instruction on labor protection, you cannot simply read the instructions one by one. The briefing program should be worked out in advance, ensuring that the information is understood as best as possible. Diagrams, posters, and training materials will help improve your understanding of the material. At the same time, it is necessary to demonstrate safe working methods.

Initial training at the workplace

Initial briefing is a necessary procedure in labor protection, and it is needed so that already at the workplace where the employee will work before starting to perform duties and assignments in this organization, he becomes familiar with all the necessary safety rules that must be observed so as not to endanger your life and the lives and health of your colleagues.

That is, as you understand, the purpose of the initial briefing is for the employee to begin performing his duties having already been familiar with the following important points in everyday work:

- production environment;

- instructions used in the work;

- what work procedure is considered safe;

- the tools and equipment used, devices and mechanisms;

- sources of increased danger (if any);

- the nature of production work.

Therefore, my goal and the goal of conducting initial training at the workplace is, firstly, to form the correct thinking of employees about safety at work, in order to reduce - and preferably completely eliminate - the level of injuries and avoid emergency situations, and secondly, to sign all relevant documents so as not to be held responsible for those who do not intend - through their stupidity or chance - to comply with the rules, being familiar with them.

Let's move on and look at what primary instruction is in its narrow segments.

Who receives initial training at the workplace?

As I already said at the very beginning, initial training at the workplace, no matter what, must be carried out and without it it is under no circumstances possible to begin work.

In my personal practice, there have been no sad cases when no instructions were given and an accident occurred, but colleagues talk and share “jambs”, because if the person in charge missed such an important procedure, then this is, in general, nonsense.

An example from the practice of colleagues - a serious accident occurred in the organization, and all because a recently hired young and inexperienced employee was not given initial training, so he did not know that special equipment could be moving throughout the territory and even in the workshops.

And he was also not aware that listening to music with headphones at work is strictly prohibited, because you may not hear warning signals, which soon, in fact, happened: he came around the corner of the building and because of the loud music he did not I heard a forklift working around the bend.

The driver backed up and hit a person. Fortunately, the speed was low, and he still noticed the boy, however, he was unable to brake immediately and as a result, multiple fractures of both legs and a long sick leave. And the employer has an investigation, inspection and a lot of fines, in addition to the failure to conduct initial training at the workplace.

Therefore, let’s take a closer look at who is required to undergo initial training at the workplace:

1. Newly hired employees who will use any tools, possibly equipment, units and mechanisms during the working day, including:

- employees with whom fixed-term employment contracts were signed;

- combined responsibilities;

- working remotely (at home);

- sent to you from another unit.

2. Employees who are assigned to perform work that is new to them.

3. Employees of an outside organization sent on a business trip to your company.

4. Trainees.

5. Other workers who take part in the work of the organization, but related to the production side.

6. Employees employed under the GPC and participating in the functioning of the company from its production side.

All of the listed options for people entering the area of responsibility of your organization undergo initial training at the workplace without exception! And it doesn’t matter, for example, that this is an employee of a third-party organization doing something in your backyard.

In the GPC (civil legal nature) agreement, be sure to specify the duties and responsibilities of the parties in terms of ensuring safe conditions and labor protection; thus, you can immediately earn several advantages in creating an occupational safety system at your enterprise. This recommendation is also stated in Letter of the Ministry of Labor No. 15-2/OOG-1157 dated May 17, 2019.