What instructions should the company have?

Article 212 of the Labor Code of the Russian Federation states that the employee must be informed about all the risks, harmful and hazardous production factors at a particular workplace. The employee must know what protective measures he is required to use to eliminate health hazards.

Therefore, labor safety instructions must be developed at each workplace, depending on the tools, equipment, machines used by employees, as well as work conditions, for example, working at heights, working in electrical installations, working in confined spaces.

Each enterprise must have its own unique list of occupational safety instructions. Safety instructions are mandatory for all enterprises:

- when working on a PC and other office equipment.

- during operation, maintenance and repair of equipment

- during hot work

- when working at height

- when performing electric and gas welding work

As you can see, instructions are developed either by type of work or by profession. But there are also additional instructions, for example, when carrying out traveling work, when sending on a business trip, etc.

Who develops, coordinates and approves labor safety instructions

Before being allowed to work independently, workers must be familiarized with the labor safety instructions and tested for knowledge of safe techniques and work performance skills. This is the task of every immediate manager.

At the same time, monitoring the conduct of briefings and providing methodological assistance in developing instructions is the responsibility of a labor protection specialist .

The help of an occupational safety specialist consists of checking the correct application of regulatory legal acts, but safety measures for department heads and immediate supervisors need to be gleaned from the operating manual and labor protection rules.

Note! Article 212 of the Labor Code of the Russian Federation directly states that the employer coordinates draft rules and instructions on occupational safety with a representative body of employees, for example, a trade union.

Thus, approval of the instruction and its entry into force is impossible without the agreement of employee representatives. If such a body has not been created in the organization, it is necessary to create it if there is such an initiative. The initiative, we remind you, can come not only from the employees themselves, but also from conscious employers.

The role of the OT service is to provide methodological assistance, and then to monitor the correct application of the legislation and the training itself.

At many enterprises, instructions are drawn up by an occupational safety specialist, and then transferred to the department for signatures. This is incorrect and contradicts not only the Procedure for training and testing knowledge of labor protection requirements No. 1/29 of 01/13/2003, but also the regulations on the occupational safety and health system developed and approved at each enterprise (section - distribution of responsibilities of labor protection officials).

Alternatively, the safety specialist, together with the immediate supervisor in the department, develop instructions together, but only if the enterprise and the developer have no idea how to draw up this document.

After the department has prepared a draft instruction, a labor protection specialist reviews it, makes his comments or additions, and returns it to the developer for revision.

After this, once the instructions are corrected and the occupational safety specialist confirms this with his signature in the approval field, the instructions are submitted to the trade union committee for approval. Then, after the draft instructions are marked for approval, the project must be submitted for inclusion in the order for approval by the head of the organization.

Note! How to familiarize an employee with the occupational safety instructions must be indicated either in the training regulations, or in the regulations on the occupational safety management system, or in the order itself to put the instructions into effect.

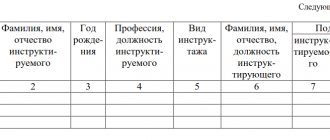

As a rule, employees sign the introductory sheet for the instructions. It is recommended to create separate journals for issuing instructions on labor protection, but not prescribed in regulatory legal acts.

Initial briefing

This training is carried out with employees at their workplace by the head of the production unit, before new employees begin working independently. The event is held with the following categories of workers:

- With each employee who came to the work unit, including persons temporarily hired for seasonal work, part-time workers, as well as those working at home using mechanisms, tools and materials provided for these purposes by the employer or purchased by the employee at his own expense.

- With employees of the organization on a temporary or permanent basis, transferred from other structural divisions, coming to a new workplace.

- With seconded employees of other enterprises, students of educational institutions sent for practical training.

Initial safety training is carried out on the basis of developed and approved instructions and training programs to ensure that the employee acquires the appropriate knowledge sufficient to safely perform his job duties.

The program of such events necessarily includes:

- familiarization with the technology of work at the future workplace;

- studying the design of equipment, high-risk areas and the procedure for fencing them;

- studying measures in preparation for work (checking the equipment, its grounding and switching devices, the tools used);

- rules for the use of safety and protective devices;

- familiarization with the requirements for workwear and personal protective equipment;

- description of typical cases of industrial injuries and the reasons that led to them;

- studying safety rules in relation to electrical equipment and lighting devices;

- familiarization with the rules of safe work performed jointly with other persons;

- studying the rules of medical care and personal hygiene measures for workers;

- familiarization with the responsibility of workers in case of non-compliance with safety regulations.

Each employee undergoes initial training separately and demonstrates safe work methods. The hired employee undergoes an internship at the future workplace, with a number of shifts determined by law, under the supervision of an experienced employee or his immediate superior.

At the end of the internship, a knowledge test is carried out and a mark is made in the briefing log about the employee’s permission to independently perform duties.

Employees whose duties do not include performing work related to equipment, using power tools and storing, using materials and raw materials may be exempt from undergoing initial training. The list of relevant positions and specialties is approved by the chief engineer of the organization.

Video: Initial briefing on labor protection

On the basis of what documents are instructions developed?

Safety instructions are developed on the basis of labor protection rules, operating instructions, taking into account the job responsibilities of a particular employee . If an employee performs part-time work, then he needs to be familiarized with the instructions both at the main and at the combined workplace.

But if both electric forklifts and forklifts are used in the same workshop, it is necessary to develop instructions for each type of fuel, even though the worker has the same profession - forklift driver. Therefore, instructions are developed in strict accordance with the type of equipment or machines being serviced. In one case, the fuel system is gasoline, and in the other, it is powered by electric energy. Accordingly, security measures will differ.

Concept of labor protection

Occupational safety is a set of rules of behavior, measures and special events, the purpose of which is to preserve the health and life of employees. The employer is obliged to ensure labor protection in accordance with legislative acts, ranging from the Labor Code to local documents. There are no exceptions: an organization that does not take care of the safety of its employees is breaking the law.

Occupational safety (OS) is a complex of the following elements:

- industrial sanitation, that is, the reduction and prevention of damage to health in hazardous industries;

- electrical safety;

- fire safety;

- occupational hygiene, that is, preventive measures that prevent or reduce harm to the employee;

- life safety;

- occupational safety management.

All organizations are required to ensure occupational safety: this function can be performed by a manager or an individual specialist.

Conducting briefings with employees is part of occupational safety management. The employer, for its part, is obliged to create the most comfortable conditions for employees, and they, in turn, must know and follow all the rules. Thus, OT manifests itself as an interaction between two stakeholders. Workers avoid injuries and stay healthy, and the organization maintains a healthy workforce, saves on insurance payments and lawsuits, and avoids claims from regulatory authorities.

If an accident occurs at an enterprise, a protocol must be drawn up. Based on this document, regulatory authorities decide whether the employer has fulfilled its labor protection obligations, including whether it has provided instructions.

Frequency of revision of instructions and their validity period

The instructions require revision if:

- there was a change in the technological process

- replacement of production equipment was required

- personal or collective protective equipment has changed

- the materials and (or) raw materials used in production have changed, as a result of which the level of factors specified in the instructions that affect workers has changed

When introducing new jobs, instructions should be developed no later than the new employee starts work. Therefore, if the technological process has not been carried out at the workplace before, before the work begins, employees must be trained on the new instructions.

The validity period of occupational safety instructions is not established by law. The employer has the right to do this independently. At the same time, for electrical technical personnel, the period for reviewing instructions is once every 5 years.

Standard instructions on labor protection: sample 2021

For more than fifteen years, ministries and departments have refused to develop standard instructions on labor protection, since their use was logical only in a planned economy, with the same equipment of workplaces.

In this case, a labor protection specialist can develop a sample layout of the instructions and send it to the heads of departments so that they draw up all sections of the instructions according to one sample.

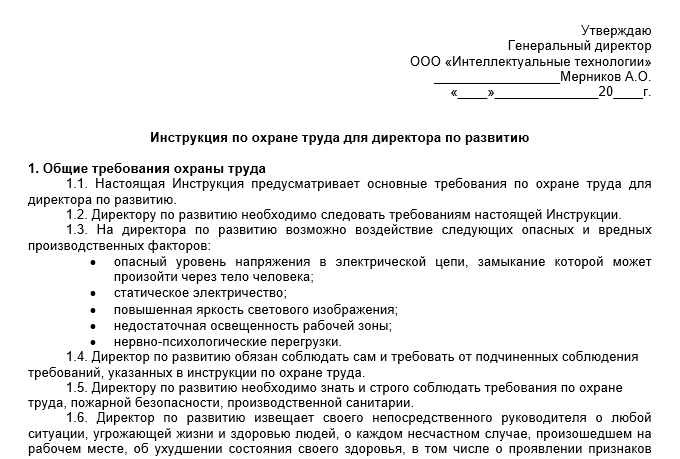

Sample labor safety instructions

What are the safety instructions?

Before starting to perform their duties, each employee is required to receive several types of instructions on labor protection: introductory, primary, repeated, targeted and unscheduled.

Before admitting a new employee to the workplace, he must be provided with introductory and initial briefings, as well as an internship for a certain number of work shifts, under the guidance of an employee appointed by order.

An employee can be allowed to work independently only after an internship and passing a safety exam.

Video: Occupational safety briefings and rules for filling out logs

Induction training

All newly hired employees are required to undergo such an event, regardless of length of service and previous work experience in their position or workplace, education, duration and type of employment agreement between the employee and the employer.

Introductory briefing is carried out by a labor protection specialist or an engineer authorized by an enterprise order to conduct briefings and take safety examinations. To carry out such an event, a program and instructions must be developed, approved by the head of the enterprise.

Completion of the introductory briefing must be confirmed by an appropriate mark in the briefing registration log, the signature of the instructor and the employee himself, as well as a record with the number of the employment order.