Electricity poses a particular danger to humans, therefore only qualified personnel can operate electrical installations and electrical equipment. The level of qualification is determined by the understanding of the danger of electric current, knowledge of electrical engineering, electrical installations, and the ability to provide first aid to victims. In accordance with this, the employee is assigned an electrical safety group. But first it is necessary to organize training on electrical safety. To do this, use the following documents:

- Order of the Ministry of Labor of Russia dated July 24, 2013 No. 328n “On approval of the Rules for labor protection during the operation of electrical installations”;

- Order of the Ministry of Energy of Russia dated January 13, 2003 No. 6 “On approval of the Rules for the technical operation of consumer electrical installations”;

- Resolution of the Ministry of Labor of Russia, Ministry of Education of Russia dated January 13, 2003 No. 1/29 “On approval of the Procedure for training in labor protection and testing knowledge of labor protection requirements for employees of organizations.”

Who should be trained in electrical safety?

Training in electrical safety rules is necessary to one degree or another for almost all employees. The organization's personnel are divided into:

- non-electrical personnel - workers not directly associated with electrical installations, but who are at risk of electric shock;

- electrical personnel - those who are involved in installation, adjustment, maintenance, repair of electrical installations and control their operating mode. It is divided into:

- administrative and technical;

- operational;

- operational and repair;

- repair.

- electrical engineering personnel who use electrical equipment in their work.

Non-electrical personnel only need to undergo training to receive group I in electrical safety. Electrical and electrical engineering personnel need more serious training and group II-V in electrical safety. Workers with higher professional education in the field of electric power industry can be assigned group II without prior training under a 72-hour program. If you do not have such education, you need to study at a specialized training center for a 72-hour program. Further, electrical safety groups are assigned depending on the accumulated experience:

| Electrical Safety Group | Minimum experience in electrical installations | |||

| Employees | ||||

| with basic general education | with secondary education | with primary vocational and higher vocational (technical) education | with higher professional (technical) education in the field of electrical energy | |

| III | three months in the previous group | two months in the previous group | two months in the previous group | one month in the previous group |

| IV | six months in the previous group | three months in the previous group | three months in the previous group | two months in the previous group |

| V | two years in the previous group | one year in the previous group | six months in the previous group | three months in the previous group |

When transferring an employee engaged in servicing electrical installations with voltages below 1000 V to work servicing electrical installations with voltages above 1000 V, he cannot be assigned an electrical safety group higher than III.

Creation of an attestation commission

At enterprises where it is required to test knowledge in the field of electrical safety, a certification commission is created or contracts are concluded with a third-party organization that has the right to conduct certification.

The composition of the commission is determined by order of the enterprise; the commission includes:

- Chief Power Engineer. This is an official who has the highest electrical safety group. Group can be 4 if the facility operates technical devices with voltages up to 1000 V, and also 5 - if the voltage of power equipment is over 5000 V.

- Deputy managers or chief engineer, safety engineer, these categories of employees are required to have at least 4 access group.

- Heads of facilities in this division.

What are the requirements for commission members:

- electrical safety certification must not be expired;

- it is necessary to be certified at Rostechnadzor or with a representative of this organization directly at the enterprise;

- You must have identification on hand.

The commission is created from an odd number of members; this requirement must be fulfilled, since when resolving controversial issues, voting will be required and this is how it can be determined whether the employee is certified or not.

The organization independently chooses who specifically to include in the Certification Commission (AC).

Training program

Depending on the assigned group, the electrical safety training program may include:

- fundamentals of legislation on technical regulation and industrial safety;

- general labor protection rules, including rules for admission to work, regulatory documents on the design and safe operation of electrical installations;

- basics of electrical engineering;

- rules for releasing the victim from the effects of electric current, providing first aid to victims at work;

- rules for the use and testing of protective equipment;

- other rules, regulatory and operational documents of the enterprise.

How often is it necessary to conduct employee certification?

The Russian Ministry of Energy has approved the frequency of testing knowledge on electrical safety. All knowledge about safety precautions in the workplace is divided into types: primary and periodic. And periodic knowledge is divided into two more types: regular and extraordinary.

periodichnost-proverki-elektrobezopasnost

The next test of knowledge on electrical safety is carried out:

- For workers involved in the repair and installation of electrical installations, a regular test of knowledge on electrical safety is assigned. The deadline for its completion must be set by a labor protection specialist.

- Technical workers need to test their knowledge of electrical safety every 3 years.

Extraordinary electrical safety check:

- workers undergo such testing if equipment using new technology is installed.

- An extraordinary test of knowledge on electrical safety is necessary in case of a break from professional activities for six months.

- when receiving a position that requires different knowledge than the previous one.

- If an injury occurs during work, a commission is formed that can prescribe mandatory certification.

An initial test of knowledge on electrical safety is carried out mainly for new workers who are entering this field for the first time and if more than 3 years have passed since their last job.

Internship

Operational, maintenance and operational-repair personnel undergo training. The internship program includes:

- mastering the requirements for safe operation of equipment;

- study of diagrams, production instructions and labor protection instructions;

- practicing clear orientation in the workplace;

- acquisition of practical skills for safe work;

- studying methods of trouble-free operation, carrying out work typical for the enterprise, for example on live parts under voltage, etc.

The internship is supervised by an experienced specialist appointed by the organizational and administrative document. Depending on the internship program, which is developed separately for each position, it can last 2-14 shifts.

Test results

If the check is carried out, its results must be recorded. This will be a kind of report on the work done.

For this purpose, a protocol is provided that reflects the following information:

- full name of the enterprise where the exams were taken;

- what is the name of the document and its serial number;

- where and when the knowledge test was conducted (for example, in the meeting room, at 14.00);

- information about officials who are members of the AC;

- information about employees who need to undergo certification;

- what inspection results are noted;

- conclusion determined by commission.

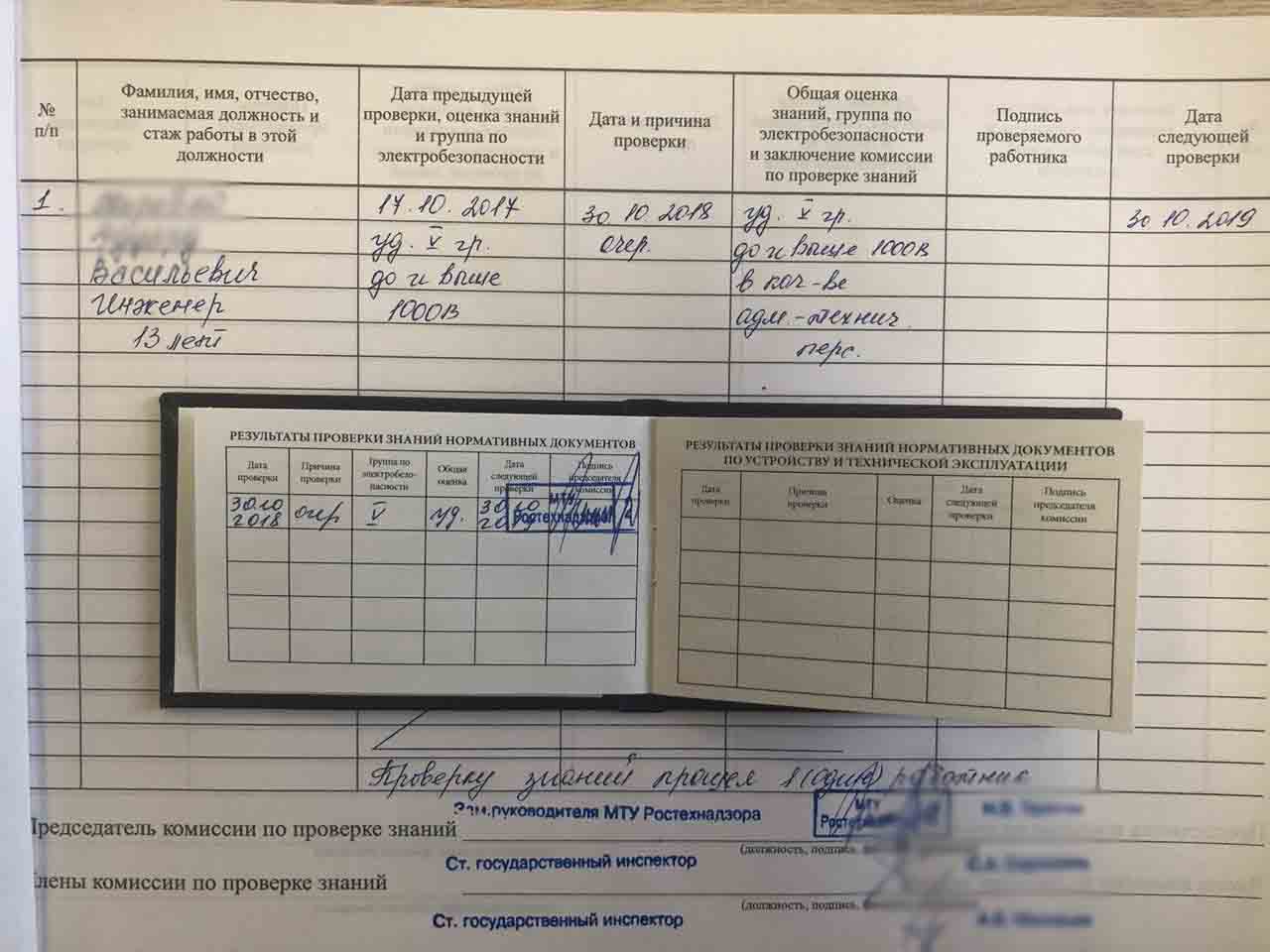

The protocol is signed by the commission members and approved by the chairman, after which certificates are issued based on this document.

Electrical safety knowledge test

To receive an electrical safety group, after training, an employee must successfully pass a knowledge test. The scope of the knowledge test depends on the requirements for personnel specified in the Labor Safety Rules during the operation of electrical installations.

Knowledge of electrical safety is tested by a commission consisting of at least five people. The chairman of the commission must have a V (for enterprises with electrical installations with voltages of 1,000 V and above) or IV electrical safety group (for enterprises with electrical installations with voltages up to 1,000 V). The remaining members of the commission should also have an electrical safety group.

The results of the knowledge test are recorded in the Logbook for testing knowledge of the rules of work in electrical installations, and employees are issued certificates in the established form.

The next knowledge test is carried out:

- once a year - for electrical personnel organizing and carrying out work on servicing electrical installations or performing adjustment, electrical installation, repair work or preventive tests in them, as well as for personnel who have the right to issue orders, orders, and conduct operational negotiations;

- once every three years - for administrative and technical personnel not belonging to the previous group, as well as for labor protection specialists authorized to inspect electrical installations.

An extraordinary test of knowledge on electrical safety should be carried out when:

- the introduction of new or revised rules and regulations;

- installation of new equipment, reconstruction or change of main electrical and technological circuits;

- appointment or transfer to another job if new responsibilities require additional knowledge;

- violation by employees of labor protection requirements;

- at the request of state supervisory authorities;

- according to the conclusion of commissions investigating accidents with people or disruptions in the operation of an energy facility;

- increasing knowledge to a higher group;

- testing knowledge after receiving an unsatisfactory grade;

- break from work in this position for more than six months.

ORGANIZATION OF TRAINING AND TESTING OF KNOWLEDGE ON STANDARDS AND RULES OF WORK IN ELECTRICAL INSTALLATIONS

Issues of training and retraining of personnel, continuous improvement of their qualifications, internships, instruction and testing of knowledge are dictated by the development of scientific and technological progress in the country and are an important problem in almost all areas of industrial production.

This problem arises especially acutely in the training and retraining of energy personnel.

In the electrical sector of enterprises (organizations), knowledge of the basics of rational and safe maintenance of electrical equipment of electrical installations is necessary for personnel at all levels - from production non-electrical, including heads of technological workshops and sections, to managers and specialists of energy services, including in some cases technical managers of enterprises (organizations).

It is for this purpose that the current norms and rules for working in electrical installations provide for a five-point differentiated scale for assessing personnel knowledge from the lowest group I in electrical safety to the highest group V with the corresponding volume of requirements and conditions for their assignment.

The current codes and regulations state that the consumer is required to ensure that electrical and electrical engineering personnel are trained and tested.

Particular attention in the rules and regulations is paid to effective forms of practical training in the workplace and preventive work with electrical personnel, such as initial, periodic and targeted briefings, internships, duplication, etc.

These forms of practical training are necessary especially for novice electrical specialists, electrical and non-electrical personnel, who, in the process of such training, must realize that electrical injuries are one of the most dangerous types of injuries, often resulting in death.

Managers and specialists of energy services of enterprises, labor protection specialists monitoring electrical installations, as well as high-level electrical specialists (for example, operational personnel, senior foremen and foremen of electrical shops, etc.) are required to undergo qualified training, retraining and testing of knowledge according to the standards and rules of work in specialized training centers (non-state educational institutions of higher professional education, training centers, etc.).

In such educational professional centers, thanks to qualified teaching staff and specialists from the state energy supervision authorities (Rostechnadzor), who take an active part in the educational process, as well as freelance teachers from design and research institutes, students receive the necessary amount of knowledge and improve their professional skills.

It is especially valuable that when training specialists in such training centers, the training programs are not limited only to norms and rules, but also include issues of organizing and planning energy production.

For example, the Moscow Institute of Energy Safety and Energy Saving (MIEE) has opened new professional retraining courses in the specialty energy saving manager (based on higher technical and higher economic education) and occupational safety manager (based on higher technical and higher legal education).

In addition, such training centers provide their students with all the necessary regulatory, reference and technical literature, introduce them to the latest developments in the field of energy, instructional materials and methodological developments of higher departments and supervisory authorities.

Training programs for the remaining electrical personnel, indicating the necessary sections of the rules and instructions in accordance with the requirements of the rules and regulations, are drawn up by the managers (responsible for electrical equipment) of the enterprises.

This training system makes it possible to fulfill the basic requirement of current standards and regulations: the operation of electrical installations must be carried out by trained electrical personnel.

The current PTEEP finally (after lengthy discussions and clarifications) determined that knowledge testing of those responsible for electrical equipment, their deputies, as well as labor protection specialists monitoring electrical installations is carried out only in the Rostechnadzor commission.

To test the knowledge of the rest of the electrical and electrical engineering personnel of the enterprise (organization), the head of the consumer must appoint a commission consisting of at least 5 people, whose qualifications and electrical safety groups must meet the requirements of PTEEP.

A mandatory requirement of these rules is that all members of the commission have an electrical safety group, which they must obtain when testing their knowledge in the commission of the Rostechnadzor body.

It is allowed to test the knowledge of individual members of the commission on site, provided that the chairman and at least 2 members of the commission have passed a knowledge test in the commission of Rostechnadzor bodies.

In accordance with PTEEP, at least 3 members of the commission must be present during the knowledge testing procedure, including necessarily the chairman (deputy chairman) of the commission.

If the number of consumer employees does not allow the formation of knowledge testing commissions, then it should be carried out in a commission of Rostechnadzor bodies.

Currently, commissions of Rostechnadzor bodies, as a rule, began to be created at specialized educational institutions (training centers) and appointed by order of the head of the Rostechnadzor body. Members of such a commission must undergo a knowledge test at the Rostechnadzor body that issued permission to create such a commission. A senior state inspector (state inspector) for energy supervision is appointed as the chairman of the commission.

In this case, according to the author, there is some discrepancy with the fact that, at the request of PTEEP, testing knowledge of the norms and rules of work in electrical installations with the subsequent issuance of a certificate is admission to work and maintenance of electrical installations, as well as to their control. The majority of commission members in educational institutions are teachers, and not personnel who require such access to servicing electrical installations, and therefore they do not need to undergo testing of knowledge of work norms and rules.

The rules [5, 6] allow, and in specialized educational institutions, control and training machines based on personal electronic computers (PC) are successfully used for all types of testing, except for the primary one.

If, when using a PC, the person being tested received an unsatisfactory assessment, which may well be the case, then the commission asks him additional questions and, based on the results of such a survey, a final assessment of knowledge takes place.

There are a significant number of specialties in the electric power industry, personnel for which must undergo specialized training and improve their qualifications under special programs. Such specialties include, for example, servicing relay protection and automation devices [14], setting up and testing electrical devices, working with information-measuring automated monitoring and control systems, etc.

There is an urgent need for such personnel in almost all industries, both in the design and installation, commissioning, testing and operation of electrical installations.

Moreover, the level of qualifications, for example, of specialists in relay protection and protection devices, their ability to correctly calculate the settings of protection and automation devices will increase the level of operational reliability of these devices, reduce the possibility of emergency situations in electrical installations, improve the quality of consumed electricity, etc.

Therefore, the economic effect from training, retraining and testing the knowledge of such personnel will certainly cover the costs of these expense items. Thus, the acquired knowledge becomes the most valuable commodity.

The amount of knowledge on the norms and rules of work in electrical installations at enterprises (organizations), which is required to obtain a particular electrical safety group, is established by the person responsible for electrical equipment, taking into account local conditions and job regulations.

The required amount of knowledge for managers and specialists of energy services of enterprises (organizations), as well as for labor protection specialists monitoring electrical installations, is regulated by training programs in educational professional institutions.

Of interest are the training programs developed at MIEE for the specified contingent of students, which additionally include questions for each section of the curriculum to prepare them for testing their knowledge of work norms and rules.

In order to facilitate the assimilation of educational material on each issue, it is indicated in which normative document and in which of its sections this material is presented [15]. This significantly increases the efficiency of the learning process and testing students' knowledge.

As for training programs on the norms and rules of work in electrical installations for training and testing the knowledge of other electrical and electrotechnological personnel directly at enterprises (organizations), they must be developed taking into account the specifics of a particular production and approved by Rostechnadzor.

As an example, below is a training program for electrical and electrical engineering personnel at textile and light industry enterprises, which is approved by Energonadzor.

The program consists of an introduction, which shows the specifics of the operation of electrical installations at enterprises of these industries, and eight sections reflecting the basic requirements of the current standards and regulations for work in electrical installations (MPBEE, PTEEP, PUE, etc.).

Training program

“Norms and rules for working in electrical installations”

for electrical and electrical engineering personnel at textile and light industry enterprises

Introduction

Ensuring rational and safe operation of electrical installations at textile and light industry enterprises is an acute problem, which is determined by the specifics of the operation of electrical equipment and the insufficiently high professional qualifications of electrical and electrical engineering personnel at enterprises in these industries, including:

the presence of particularly hazardous premises (for example, dyeing, drying, ironing and production facilities with a chemically active environment);

a wide variety of types of hand-held electric machines, power tools (electric irons, electric cutters, electric drills, etc.) and local lighting lamps (lighting on machines and machines);

crowding of production equipment and the presence of live parts accessible to touch for production personnel;

the lack of trained and certified electrical personnel and workers at electrical installations in most enterprises, which aggravates the problem of electrical safety.

If for those responsible for electrical facilities, their deputies and occupational safety specialists who control electrical installations, training and certification centers have been created and operate in the Rostechnadzor commissions, then for electricians, electricians, foremen and electrical workers there are no such opportunities.

This program is intended for electrical and electrical engineering personnel during training directly in production conditions.

Program content

Section 1. Current norms and rules for work in electrical installations.

Interindustry rules on labor protection (safety rules) during the operation of electrical installations (IPBEE).

Rules for the technical operation of consumer electrical installations (PTEEP).

Rules for the construction of electrical installations (PUE) including sections of the 7th edition (1, 2, 4, 6, 7) and chapter 1.8 “Acceptance test standards”.

Instructions for the use and testing of protective equipment used in electrical installations (IPISZ).

Norms and rules of work as a system for organizing rational and safe operation of electrical installations.

Section 2. General provisions of current standards and regulations when working in electrical installations.

Scope and procedure for application of MPBEE, PTEEP, PUE and IPISZ. General requirements of norms and rules for working in electrical installations. General provisions for the design and operation of electrical installations.

Terms and definitions used in the norms and rules of Rostechnadzor.

Ensuring compliance with norms and rules of work in electrical installations.

Section 3. Requirements for personnel and their training.

Personnel tasks, responsibility and supervision of compliance with the norms and rules of work in electrical installations.

Characteristics of administrative and technical, operational, maintenance, operational and repair electrical personnel. Characteristics of electrical engineering personnel.

Electrical safety groups and conditions for their assignment.

Section 4. Operational management of electrical equipment.

System and organization of operational management of electrical equipment of the enterprise.

Operational maintenance and inspection of electrical equipment.

Operational switching. Switching order in electrical installations.

Section 5. Procedure and conditions for safe work in electrical installations.

Category of work in electrical installations, their characteristics.

Organizational measures to ensure work safety. Those responsible for the safety of work, their rights and responsibilities. The procedure for organizing work according to order, order, or performed in the order of routine operation according to the list. Brigade composition.

Technical measures to ensure the safety of work with stress relief.

Safety measures when performing individual works (when working with hand-held power tools and electrical machines, portable lamps, on electric motors, switching devices, transformers, on cable and overhead power lines, capacitors, etc.).

Section 6. Grounding and protective electrical safety measures.

Types of industrial electrical networks in relation to electrical safety measures. Methods for performing grounding.

General requirements of the PUE for measures of protection against electric shock. Types and methods of protection against direct and indirect contact in electrical installations with voltage up to 1 kV.

Grounding devices for electrical installations with voltages up to 1 kV in networks with a solidly grounded neutral.

Insulation of electrical installations. Basic measures to ensure electrical safety:

grounding of electrical installations;

residual current devices (RCDs);

use of double or reinforced insulation;

potential equalization;

equalization of potentials;

protective electrical separation of circuits using isolation transformers;

use of low voltages, etc.

Section 7. Rules for the use and testing of protective equipment used in electrical installations.

Scope of application of IPIS. Procedure, classification and Instructions for the use and testing of protective equipment used in electrical installations. The order of their content.

Monitoring the condition of protective equipment and recording them.

Technical requirements for certain types of protective equipment. Norms and terms of operational and acceptance tests of protective equipment.

Section 8. Rules for releasing victims from electric current and providing them with first aid.

Practical conditions for the occurrence of electrical damage. The effect of electric current on the human body. The procedure for freeing the victim from live parts that are energized.

Rules for providing first aid to a victim.

The program and process for training managers of operational personnel and workers from among operational, operational and repair personnel are somewhat specific, which should include internship and knowledge testing, and for managers of operational personnel, workers from among operational and operational maintenance personnel, also duplication.

The current PTEEP regulates in sufficient detail the requirements for the procedure for obtaining admission to internship and duplication, their duration and volume, with subsequent admission to independent work in electrical installations.

Responsibility for the correct actions of the trainee during duplication lies with both the trainee himself and the employee teaching him. This situation in PTEEP is quite serious, since during duplication the trainee is allowed to carry out operational switching, inspections and other work in electrical installations under the supervision of the trainee.

Practice has shown that the considered system of training and testing knowledge of the norms and rules of work in electrical installations is quite effective and covers the entire contingent of specialists who carry out all types of work in electrical installations and supervise their rational and safe maintenance.

Table of contents

Duplication

In addition to the internship, operational and operational repair personnel must undergo duplication, during which the trainee can carry out operational switching, inspections and other work in electrical installations only with the permission and under the supervision of the trainee. During the duplication process, control emergency and fire drills are also carried out.

The duration of duplication is determined by the knowledge testing commission depending on the employee’s professional training, length of service and experience. Duplication can take anywhere from two to 12 shifts.

Requirements for employees to be tested

What are the requirements for a manager?

- The electrical safety group must correspond to the voltage consumed.

- An official who is entrusted with responsibility for electrical equipment is appointed to the position of chairman.

- The inspection group must not be lower than that of the employee being certified.

The following requirements apply to examiners:

- Mandatory certification in the territorial division of Rostechnadzor. It is allowed for two employees to undergo a knowledge test at the state energy supervision, and all the rest at the enterprise itself.

- If the structure of the organization is large enough, then such commissions are created at each facility. This makes it more convenient to work and carry out checks.

- The AC may include representatives of supervisory authorities; they are included by agreement.

- If the enterprise employs a small number of employees, then it is enough to take exams directly at Rostechnadzor, and the creation of commissions will not be advisable.

Responsibility for lack of electrical safety training

Failure of employees to receive appropriate training in electrical safety may result in the employer being fined (Article 9.11 of the Code of Administrative Offenses of the Russian Federation):

- for an official - from 2,000 to 4,000 rubles;

- for individual entrepreneurs – from 2,000 to 4,000 rubles or administrative suspension of activities for up to 90 days;

- for legal entities - from 20,000 to 40,000 rubles or administrative suspension of activities for up to 90 days.

In the event of a situation (due to negligence) causing serious harm to the health of an employee(s), or death, the person responsible for compliance with labor protection requirements bears the appropriate punishment (Article 143 of the Criminal Code of the Russian Federation):

| causing serious harm to human health |

|

| death of a person |

|

| death of two or more persons |

|

comments powered by HyperComments

Share news:

The entry was published on September 27, 2015 by Olga Larionova in the Electrical Safety section.

Rights and obligations of the commission

Approved qualified specialists establish the level of knowledge of hired employees.

Work is determined exclusively on an individual basis:

- Members of the examination group initially form a list of questions that will be asked during testing, referring to their position and work experience.

- The current level of knowledge in the area under consideration is checked. The chairman or his deputy must be present during testing - according to the management, they can conduct testing together.

- Assignment of an electrical safety group based on the results of the passed exam. Based on the results, a decision is made whether to assign a group or not.

- Issuance of a confirmation certificate.

Certificate confirming successful passing of the test

We advise you to study Cable Trays

The results of the testing must be recorded in a specially developed internal Protocol. In the event of an unsatisfactory assessment, data about this must also be recorded in the document. As a rule, this entails a retake within the established time frame - until this point the permit is not issued, otherwise the employer will be subject to administrative liability in the form of a fine.