Enterprise safety

From this article you will learn how occupational health and safety at work is organized, who is responsible for the safety of workers, why an occupational safety service is created at an enterprise, how it works and who controls it.

Occupational health and safety at an enterprise is a set of measures necessary to protect workers while performing tasks assigned by the employer. According to their areas of work, they are divided into:

• ensuring the safety of electrical equipment, cable lines, power lines, lightning protection; • protection from fires, fires and smoke; • safe organization of all categories of work; • maintaining the serviceability of equipment (verification, repair, timely replacement); • maintaining buildings for various purposes, structures, structures, as well as the territory in proper condition; • neutralizing the impact of noise, dust, vibration and other harmful factors on workers; • protection of people who work in dangerous conditions: at heights, underground, in conditions of high or low temperatures, various radiations, in contact with hot or moving objects and their parts, etc.; • training of workers, students, management personnel (instructions on labor protection and safety, special courses, posters, diagrams, drawings, etc.); • monitoring of health indicators of workers (preliminary, pre-shift, annual, extraordinary medical examinations and examinations), organization of sanatorium treatment, provision of therapeutic and preventive food, milk; • public monitoring of the organization of occupational health and safety at the enterprise: the work of occupational safety officers, trade unions, and other public associations.

Taking into account the requirements of regulatory documentation that regulates the activities of specific organizations, they develop their own OSH standards. All the information employees need on the safe conduct of work is set out in the occupational health and safety instructions for specific professions or the performance of certain work (loading and unloading, fire, etc.).

Safety precautions

The definition is given in GOST 12.0.002-80 System of Occupational Safety Standards (SSBT). Terms and definitions (cancelled).

Safety precautions are a type of activity (a system of organizational and technical measures, protective equipment and methods) to ensure the safety of any human activity, including work activity. Previously, science, the subject of which is this type of activity, also used the same name, but currently the discipline of syndication is developing with a wider range of subject areas, absorbing the subject of safety science.

Notes:

1 From the position of occupational safety, the term “safety” is more narrowly understood as protecting workers from exposure to hazardous production factors.

2 From the position of labor protection, the term “safety precautions” means the protection of employees and persons equivalent to them from the effects of hazardous production factors, which is one of the main parts (occupational safety) of labor protection in general.

The definition is given in GOST 12.0.002-2014 System of Occupational Safety Standards (OSSS). Terms and definitions (Replaces GOST 12.0.002-80 System of occupational safety standards (SSBT).

Occupational safety (OH) is an outdated term that denoted part of the function of “occupational safety” - the management of production activities aimed at preventing injuries and illnesses associated with production. Currently, it is practically not used and does not appear in official documents.

The modern name of the function in Russia and the CIS countries is “occupational safety (OH)”, in international ones / “Health and Safety”. The sphere of “occupational safety” only to a small extent coincides with the sphere of “safety precautions” (“health and safety”). “Labor safety” includes, first of all, legal issues - the rights and obligations of workers and employers to ensure compliance with the requirements of the Labor Code.

“Safety”, on the contrary, means a set of requirements for the behavior of workers and the performance of their work functions, aimed at preventing dangerous situations for the life and health of both the workers themselves and their environment. In the terminology of the Labor Code of the Russian Federation, an analogue of the concept of “safety precautions” is the concept of “safe methods and techniques of work”. However, the content of this phrase is not disclosed in labor legislation and other regulatory legal acts.

In accordance with clause 5.3.3. Section 5.3 Training, qualifications and competence of personnel GOST R 12.0.006-2002 System of occupational safety standards. General requirements for occupational safety management in an organization (cancelled):

The organization shall establish methods to demonstrate that the employee has appropriate knowledge regarding:

— employee responsibilities in the field of labor protection in accordance with current legislation;

— actual or potential consequences of its activities on occupational safety;

— understanding of responsibility for compliance of his actions with the organization’s policy in the field of labor protection, safety requirements, labor protection management system, including the employee’s actions in emergency situations;

— possible consequences of non-compliance with technological instructions.

Change No. 1 GOST R 12.0.006-2002 System of occupational safety standards. General requirements for occupational safety management in an organization

Adopted and put into effect by Resolution of the State Standard of Russia dated June 26, 2003 No. 206-st. Date of introduction 2004-01-01 (cancelled):

The name of the standard should be stated in a new edition: “System of occupational safety standards. General requirements for the occupational safety management system in an organization"

Clause 5.3.3. Third paragraph. Replace a word; “security” to “security level”;

fourth paragraph. Replace the words: “safety precautions” with “occupational safety”;

The last paragraph after the word “technological” should be supplemented with the words: “processes and production”.

New version of clause 5.3.3 The organization must establish methods to confirm that an employee has relevant knowledge regarding:

— employee responsibilities in the field of labor protection in accordance with current legislation;

— actual or potential consequences of its activities on the level of occupational safety;

— understanding of responsibility for the compliance of his actions with the organization’s policy in the field of labor protection, labor protection requirements, labor protection management system, including the employee’s actions in emergency situations;

— possible consequences of non-compliance with technological processes and production instructions.

Thus, from January 1, 2004, “safety precautions” was replaced by “labor protection” and organizations (enterprises, factories, plants, institutions, educational institutions, etc.), regardless of their organizational and legal form, should not establish methods confirming that the employee has the appropriate knowledge regarding safety requirements, and must establish methods that confirm that the employee has the appropriate knowledge regarding labor protection requirements.

Occupational safety and health at the enterprise: main points

Labor safety rules were not just invented by legislators. They provide protection to employees from accidents, and in the event of unforeseen incidents that cause injuries at work, they guarantee that the employee will receive some kind of compensation.

For each type of work, the Labor Code defines its own requirements. Administrative employees are required to monitor their compliance, just like compliance with sanitary standards and rules. Performers directly involved in production processes must strictly follow the developed labor protection instructions.

Each employee must contribute to the creation of a safe production and, if any malfunctions are detected in the operation of equipment or disregard for labor safety standards on the part of other people, he is obliged to notify his employer about this.

This will allow you to avoid traumatic situations and take timely measures to ensure their further prevention.

How to organize a labor safety management system in an organization?

Labor protection legislation

Occupational safety and health is aimed at preserving the most important resources of the state – human resources. It is considered one of the elements of social protection, allowing citizens to realize their rights. At the same time, compliance with the guarantees established by the state is mandatory.

- The right to work in conditions that meet established standards. Securing these requirements in the employment agreement.

- Suspension of work for the period of elimination of labor protection violations that arose due to the fault of the enterprise. During this time, the employee must be paid wages and retain his job.

- If hazardous health factors arise, providing the citizen with another place of work or paying for downtime.

- Prohibition on employment without provision of protective equipment.

- Compensation for health damage caused at work through the fault of the employer.

When organizing work, responsible specialists must use legal acts approved by executive authorities at various levels, internal standards of enterprises:

- workplace safety standards;

- building regulations;

- sanitary norms and rules;

- technological design standards;

- other rules and instructions developed by supervisory authorities.

Depending on the specifics of the activity, only some of them can be used. But the main legislative act remains the Labor Code, which regulates issues of work, rest, and respect for the rights of citizens. It must be studied and followed.

General concepts

Occupational safety measures are carried out during work at different times, depending on the need. What determines the technical safety measures, and the standards to be followed are determined by legislation.

Attention! Accepted abbreviations: labor protection - OSH, safety precautions - TB.

In a specific sense, labor protection includes issues related to the following areas:

- workers' rights;

- social;

- hygiene and sanitation issues;

- organizational;

- treatment, prevention, rehabilitation, disease prevention;

- technical;

- and so on.

Occupational safety and health measures vary in scope depending on the state of the enterprise (for example, an office or a factory). They also depend on the presence of harmful conditions, etc.

Labor safety standards are created based on job responsibilities, depending on the position held. In addition, we must not forget about the facts of mistakes, accidents and possible risks, on the basis of which are created and tightened . Safety in the workplace is the key to life and health.

Occupational Safety Corner

Planning of occupational safety measures

Before starting to prepare a program, its goals and audience are determined, and the desired results are indicated. Based on the goals, ways to achieve them are selected, instructions are given to employees, and commissions are created. The commission must include those specialists whose activities are inextricably linked with the need to implement certain measures.

The effectiveness of measures depends on the time of their implementation, proper determination of the accounting procedure, and the necessary preventive actions. You must first competently justify the required technical equipment of the measures planned for implementation, their personnel and financial support, and only then can work begin. The occupational safety action plan specifies the type of activity. There are sanitary, organizational, technical and so-called “individual” measures.

Why do you need to follow safety precautions in the workplace?

The answer is obvious: “So as not to get injured.” But there are other reasons.

So, 5 reasons why you need to observe safety precautions in the workplace:

1. So that the employee remains alive, healthy and does not become disabled. Think about it, about 2,000 people die a year at Russian enterprises and about 4,000 people become disabled per year!

2. Causing damage to the health of other employees. For causing harm to the health of citizens, both administrative liability is provided (Article 5.27 of the Administrative Code) and criminal liability (Article 143 of the Criminal Code of the Russian Federation).

3. Failure to provide various benefits and guarantees not provided for by the collective agreement. Thus, many enterprises do not pay the 13th salary to violators of labor discipline.

4. Decrease in the quality of products and services.

5. Dismissal at the initiative of the employer. The administration of the enterprise has every right to terminate an employment contract for repeated violations of safety regulations or for a single gross violation of safety regulations (Articles 81 and 192 of the Labor Code of the Russian Federation).

How to correctly spell the phrase “safety rules”

The meaning of the phrase “safety precautions”

Safety precautions are a system of organizational measures, technical means and methods that prevent workers from being exposed to hazardous production factors.

All meanings of the phrase “safety precautions”

The meaning of the word "rule"

RULE, -a, cf.

1. A position expressing a certain pattern, a constant ratio of something.

phenomena. Grammar rules.

Rules of arithmetic. RULE, -a, cf.

1. Ruler for checking the correctness of the stonework.

All meanings of the word "rule"

The meaning of the word "technique"

TECHNOLOGY, -i, f.

1. The set of tools and means of labor used in social production, as well as the area of human activity associated with their production, use and improvement.

History of technology.

Development of technology. Achievements of science and technology. Advanced technology. All meanings of the word "technology"

The meaning of the word "security"

SAFETY, -i, g.

A situation in which someone, something.

not in danger. International security.

All meanings of the word "security"

Sentences containing the phrase “safety regulations”

- The competent commission concluded that this accident was the result of a malicious violation safety regulations

.

- When working with a power saw, you must strictly observe safety regulations

.

- Hydrogen requires strict compliance safety regulations

, because it is able to penetrate through the smallest pores, forming explosive mixtures with air.

- (all offers)

Synonyms for the phrase “safety regulations”

- safety regulations

- safety violation

- Fire safety

- fire safety

- safety requirements

- (more synonyms...)

Associations to the phrase “safety precautions”

- safety

- Instructor

- (more associations...)

Associations to the word “rule”

- law

- establishment

- principle

- definition

- something

- (more associations...)

Associations to the word “technique”

- car

- robots

- zootechnics

- devices

- foxtrot

- (more associations...)

Associations to the word “security”

- security

- state security

- protection

- danger

- precautionary measures

- (more associations...)

Associations to the word "rule"

- general rule

- rules of the game

- breaking the rules

- the rule is

- to break rules

- (full compatibility table...)

Associations to the word "technique"

- military equipment

- safety precautions

- with the latest technology

- the technique works

- use technology

- (full compatibility table...)

Associations to the word "security"

- state security

- country security

- security Service

- safety requires

- feel safe

- (full compatibility table...)

Morphology

- Analysis of the composition of the word “technique”

- Analysis of the composition of the word “security”

Spelling

- How to spell "rule" correctly

- How to spell the word "technique" correctly

- How to spell the word "security"

Who is responsible for worker safety?

Among workers who are superficially familiar with occupational safety requirements, there is an opinion that the occupational safety and health engineer is responsible for their safety. Actually this is not true. Their immediate supervisor is responsible for the safety of specific employees. Managers of enterprises, divisions, departments, etc. are generally responsible for occupational health and safety at work.

Responsibility for compliance with occupational health and safety requirements at the enterprise is also divided into areas of supervision and assigned to employees of appropriate competence. For example, energy service employees appointed by orders are responsible for electrical safety; immediate supervisors are responsible for organizing a system of briefings on labor protection and safety at workplaces and its quality functioning.

The workers themselves are obliged to take care of their own safety. This is a requirement not only of common sense, but also of Art. 214 Labor Code of the Russian Federation. To stay healthy and work, workers need to:

• clearly know and constantly comply with the requirements of safety and labor protection instructions; • complete training and medical examinations on time; • use PPE; • be able to provide first aid; • carefully monitor the environment, analyze production situations and immediately report to the work manager about possible or existing dangers.

During training, medical examination, or work stoppage due to a dangerous situation, the worker retains his average earnings. If he evades responsibility for his own health - does not attend instructions on occupational health and safety, does not undergo medical examinations, regularly violates occupational safety requirements - the employer’s representatives have the right to remove him from work in the appropriate manner. However, no wages are accrued during this time.

Structure

How large the occupational safety service will be, whether it will be a whole department or one specialist responsible for labor protection and industrial safety, depends on such conditions as the number of personnel, the specifics of production and the presence or absence of harmful factors, etc. To determine the required number employees can use the recommendations of Intersectoral Standards..., approved. Resolution of the Ministry of Labor of the Russian Federation No. 10 January 22, 2001. They contain specific indicators for the required staffing levels for individual functions performed by the OT service, which is very convenient for calculations.

As a recommendation, we provide the following information:

- if there are fewer than 50 employees, the employer himself can deal with occupational safety issues. Also, the duties of an occupational health and safety engineer can be performed by an employee appointed by his order (trained as an occupational safety engineer, in accordance with the Procedure for training in occupational safety..., approved by Resolution of the Ministry of Labor of the Russian Federation, Ministry of Education of the Russian Federation dated January 13, 2003 No. 1/29). The manager can also seek help from an accredited organization providing such services;

- if the enterprise has from 50 to 700 people who are not engaged in heavy and hazardous work, there is one occupational safety and health engineer;

- more than 700 people - a labor protection bureau (3-5 employees) or a department (more than 6 people) is organized (clause 3.1.1. Intersectoral standards..., approved by Resolution of the Ministry of Labor of Russia dated January 22, 2001 No. 10 (as amended on February 12, 2014) ).

Read more: How to organize labor protection from scratch

Certification of enterprises according to occupational safety

Article 212 of the Labor Code of the Russian Federation states that occupational health and safety at work is the direct task of the employer. The same article mentions SOUT and certification of the organization of work on occupational safety.

Organizes and manages the certification of the organization of work on labor protection by the central body of the SSOT (labor certification system) - the All-Russian Center for Occupational Safety and Health. Currently, HSSE at enterprises and organizations is not mandatory, but, as a rule, it is introduced on a voluntary basis - certification is carried out for compliance with both international requirements (ISO OHSAS 18002) and the requirements of national standards (GOST 12.0.230-2007). A document certifying compliance with state regulatory requirements at an occupational safety enterprise is called a safety certificate.

A special assessment of working conditions (SOUT) has been mandatory since 2014. It must be carried out in accordance with Federal Law No. 426-FZ of December 28, 2013. It is allowed to be carried out only by organizations that have received accreditation. During the SOUT, identification of workplaces and measurements of environmental parameters are carried out. For each workplace, a map is drawn up with characteristics of working conditions. Based on the results, a report is prepared, a copy of which is submitted to the labor inspectorate at the location of the organization. The data remains valid for five years, after which re-evaluation is required.

Federal Law No. 503-FZ of 12/30/2020 determined that from 01/01/2021, repeated SOUT after 5 years is not necessary if the working conditions are not harmful and there were no accidents or occupational diseases at the enterprise. If such conditions occur or working conditions deteriorate, it will be necessary to carry out an unscheduled SOUT. Conditions in hazardous workplaces will still have to be assessed every 5 years.

Which glue is the least dangerous?

You need to be careful when handling epoxy resin solutions. To work with such substances, you will need a specially configured workplace - with ventilation and a mandatory set of personal protective equipment. The second place in danger is occupied by “pencil” type glue, which requires heating - the familiar glue gun. This glue is less toxic and can be used even at home. And finally, the familiar PVA (polyvinyl acetate) glue. Despite its low toxicity, penetration into the body or onto the mucous membrane is also extremely undesirable.

Instructions

Basic requirements for TB:

- when starting to perform each type of work that has not been done before, additional instruction is needed;

- extreme attentiveness is required, it is not recommended to be distracted by extraneous conversations or affairs;

- On the territory of the plant you cannot walk around the workshops, ignore the signals of crane operators and vehicle drivers. It is imperative to bypass unloading and loading areas, and bypass places not intended for passage. You cannot touch terminals, electrical wires, equipment, fittings, lighting devices, especially with tools or scissors;

- In case of injury or any ailment, the injured person needs to stop the work process and seek medical help.

Before starting to perform direct work duties, employees must get their uniform in order, put on personal protective equipment, if necessary, and special shoes. You should also inspect the workplace, restore order, and remove unnecessary items. There should be enough light, but not blinding to the eye, it should be directed towards the work area.

It is necessary to inspect the floor - there should be no potholes, slippery areas or other defects. Hoists and hoists can only be used in good working order. When moving or lifting heavy loads, the signal must be given by one worker. The slinging is made reliable; high-strength cleats are used for mooring.

Sharpening tools on grinding wheels can only be done by first wearing safety glasses. There is a protective screen; it should not be moved to the side. Be sure to check that the tool rest is installed correctly and bring it as close to the grinding wheel as possible. You need to stand half a turn towards the wheel while sharpening. You cannot remove chips by hand.

Safety precautions when working with glue: basic rules

First of all, you need to do everything to prevent glue from getting on your skin. And most importantly - in the eyes. If trouble does occur, you should immediately rinse your eyes with plenty of cold water and consult a doctor.

By the way, at the production site there is a special installation - an eye washing station. It is activated by a hand or foot pedal: all you have to do is lean over the sink and two jets will begin to wash your eyes.

Secondly, you should ensure really good ventilation, since most adhesives are highly toxic to humans. Judge for yourself: toluene, epoxy resins, phenol-formaldehydes, hardeners... and so on. And then, many types of glue contain flammable components! So fire safety must also be kept in order.

Thirdly, use the personal protective equipment provided. To prevent glue from getting on your skin, use rubber or latex gloves. To prevent glue from getting into your eyes, wear safety glasses. And of course, to protect the respiratory system when using toxic glue - a respirator.

Instructions from safety service specialists

The Occupational Safety and Health Service monitors the safety of all types of work carried out at the enterprise. Safety engineers have the right to stop any work that is carried out in violation of the requirements of safety and labor protection instructions. At the same time, they issue orders that reflect the essence of the violations and indicate the time frame for their elimination. Ignoring the requirements of these orders by the persons to whom they were issued entails disciplinary, financial, and in especially severe cases, criminal liability.

The order includes: • the essence of the identified violations of the requirements of the rules, safety and labor protection instructions; • links to regulatory documentation, the requirements of which were violated; • time frame within which violations must be eliminated; • persons responsible for eliminating identified violations.

The order is issued to the work manager and is drawn up in 2 copies, one of which is issued to him against signature. If the work manager refuses to accept the order, a report about this is drawn up or the note “Refused to accept the order” is made on the order. If the order is refused, work is still stopped, and any violations identified must be corrected. The inspector may insist on conducting an unscheduled briefing on occupational health and safety instructions whose requirements have been violated.

As soon as the violations are eliminated, the responsible person informs the Occupational Health Service in writing. After the safety engineer checks the implementation of the necessary measures and makes the appropriate mark (+ date, signature) in the order, work can continue. Prescriptions are stored in the OT service. The order of their storage in the organization's divisions is established independently. For example, you can enter information about issued orders (the essence of violations, deadlines for elimination, responsible persons) in the occupational safety inspection logs.

Responsible persons

Occupational safety issues are usually dealt with by an occupational safety specialist or an entire department. If the enterprise is small (or there is no specialist), the manager bears responsibility. But since labor protection affects different areas of activity, certain issues not only concern engineering and technical workers, but also require the involvement of specialists in the field of law, economics, and medicine.

Tasks to ensure safety precautions should be handled by department heads and specialists responsible for the trouble-free operation of equipment. They visit workplaces every day, know production problems, and give recommendations on how to safely perform operations. Such employees are responsible for drawing up safety instructions, and the occupational safety engineer only advises on how to draw them up correctly.

Responsibilities of the employee to warn management about emergency situations

Each employee of the enterprise in the event of an injury or manifestation of an occupational disease in himself or one of his colleagues is obliged to notify management about this. The same must be done if, during work, circumstances suddenly arise that threaten the health and lives of people.

If an injury occurs, the victim must be given first aid and immediately taken to the nearest medical center. In the event of a danger that threatens people or the production process, each employee must immediately stop performing his duties and report this to his immediate superiors.

Occupational safety training

The training procedure and rules for testing occupational safety knowledge among employees of organizations were approved by Resolution of the Ministry of Labor and Ministry of Education No. 1/29 of January 13, 2003. It is designed to provide preventive measures to reduce industrial injuries and occupational diseases and establishes general rules according to which mandatory occupational safety training and testing of acquired knowledge are carried out. Instructions are carried out by an occupational safety specialist or an employee who has been assigned these responsibilities by a separate order from the employer. In addition to introductory training in occupational safety, it is necessary to conduct initial training at the workplace, repeated, unscheduled and targeted training. Issues such as safety precautions at the enterprise and in the workplace, environmental safety at the enterprise, life safety, safety of technological processes and production are addressed. The fact of the briefing is recorded in the appropriate journal under the signature of the student and the person who conducted the briefing, indicating the date of its conduct.

Differences between occupational health and safety

- Labor protection is expressed, among other things, in legal norms. Meanwhile, safety precautions are expressed only in a set of specific norms and rules that must be observed to prevent injuries when carrying out certain work.

- Labor protection does not include specific standards in its essence. And safety precautions consist of such standards. They are different for each of the industries - construction, mining, mining, etc.

- Violation of labor safety rules entails liability. Depending on the severity of the consequences, it can be criminal or disciplinary. But safety precautions are just a set of rules that are covered by the concept and meaning of labor protection. Therefore, safety precautions and their violation alone cannot lead to legal consequences.

- Labor protection is expressed in codified rules, and safety precautions are rules. These rules serve to reduce injury rates. But they cannot be binding on everyone.

Thus, safety precautions are covered by labor protection and are its specific part.

MiscellaneousComment

TB training

Safety training and knowledge testing at the enterprise are provided primarily for management personnel and workers who are responsible for safety. In addition, it is provided for persons employed in hazardous conditions. Training involves studying the basic principles of behavior in dangerous situations, general safety rules for operating equipment, completing an on-the-job internship and passing an exam to obtain an official permit to work.

Training is carried out both upon hiring and at intervals of once a year or three years.

TB training

Can a Health and Safety Engineer work part-time?

The Labor Code obliges the employer to create the position of safety engineer or an entire service if his enterprise has 50 or more employees. If there are fewer of them, the employer is allowed:

• introduce the position of occupational safety and health engineer or create a corresponding service; • do this work independently; • assign these responsibilities to another employee (the employee must have education in labor protection in accordance with the professional standard); • involve a third-party specialist.

At the same time, the employer determines the amount of time allotted to the safety engineer to perform his work independently and records this in the staffing table. Therefore, it is not prohibited for a health and safety engineer to work part-time, part-week, or part-time. To optimize calculations of the load that is planned to be assigned to one person, it is advisable to use inter-industry standards for the number of workers in the occupational safety service developed by the Ministry of Labor of the Russian Federation. This is a document of a recommendatory nature.

What is safety precautions

Safety precautions are a certain set of rules that must be followed when performing any work. It should also be noted here that violation of labor protection rules is punishable under criminal law. Responsibility for this is provided for in Art. 143 of the Criminal Code of the Russian Federation.

The immediate cause of liability under this article of the criminal code is a violation of safety regulations. For example, an employer, knowing that it is unacceptable to install bare wires without additional protection, directs an employee to perform this task in the absence of the necessary funds. The result is electric shock and serious injury to the worker. Only the employer will be responsible for this. Therefore, the concept of labor protection is broader in relation to safety precautions. It includes safety precautions.

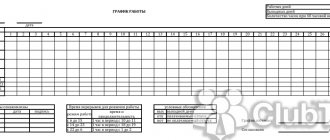

Magazines

In accordance with current legislation, logs for registering briefings at workplaces are filled out in accordance with the established form. They record all types of work performed. The employer monitors the availability and correctness of the document. If there is no log, employees of regulatory authorities may accuse management of non-compliance with labor safety rules.

Important! The journal is certified by the responsible person. The type of document production is typographic.

The filling form is used uniformly for all divisions of the company. The forms are kept by an engineer or other responsible employee. The specialist who conducts the instructions can take the log from the occupational safety engineer. The pages of the document are numbered, laced, and stamps are required.

Briefing log

The fact of conducting a briefing, regardless of its type, is recorded in a special journal, which reflects:

- data of the instructed employee;

- type of training provided;

- details of the instructions according to which the briefing was carried out;

- date of the briefing;

- instructor details;

- 2 signatures: employee and instructor.

An example of filling out a workplace briefing log, compiled in accordance with GOST, was prepared by ConsultantPlus experts. Get free access to the system and proceed to the sample.

Who controls the work of occupational health and safety services in enterprises?

Occupational safety services specialists are subordinate to the head of the organization or his deputy, so third-party organizations are needed to professionally monitor the quality of the performance of their duties. According to their affiliation they are divided into:

• state. These are specially authorized government organizations: Ministry of Labor, Ministry of Health, Gosgortekhnadzor, State Traffic Inspectorate, Gosatomnadzor, Gosenergonadzor, Gosstandart, State Fire Service, executive authorities at the federal and local levels. According to the technology of state control, it is interdepartmental. Organizations that carry it out can inspect any enterprises and associations that have objects from their area of interest;

• departmental. This is the control of subordinate organizations by superiors. Ministries, departments, parent enterprises, customer enterprises in relation to contractors can act as supervisory authorities;

• non-departmental. This is control by the Social Insurance Fund, the pension fund, other funds and policyholders;

• public. Today, social movements, foundations, the media and even individual citizens often join the traditional monitoring of the state of the production environment, compliance by workers with the requirements of labor protection and safety instructions by trade unions and authorized labor collectives for occupational safety. The attitude of enterprise administrations to safety requirements is actively discussed by users of Facebook, VKontakte, Twitter and other social networks.

Follow the link to find out more about who controls labor safety in organizations

The inspection organization notifies the enterprise in advance of the occupational safety inspection. The results of the inspection are documented in an order or other document in accordance with the regulations.

So, you have learned how occupational health and safety is carried out at an enterprise, familiarized yourself with the main areas of safety and the functions of the occupational safety service, found out who is responsible for the safety of workers, what an order to eliminate violations is, how to work with it, who controls the occupational safety service .

Please rate the site or material!

(

50

ratings, average:

4,52

out of 5)

Regulations on the Department of Occupational Health and Safety

Provisions

I. General provisions The department is an independent and structural division of the enterprise and reports directly to the chief engineer. II. Objectives 1. Organization of work to create safe working conditions at the enterprise. III. Structure 1. The structure and staffing of the department is approved by the director of the enterprise in accordance with the standard structures of the management apparatus and standards for the number of managers, specialists and employees, taking into account the volume of work and the characteristics of production. 2. The department may include divisions or individual specialists in areas of work (technical supervision engineers, compliance engineers for equipment operation, safety engineers, sanitary doctors, etc.). In small enterprises, instead of a department, a bureau is created, headed by a chief. 3. The distribution of responsibilities between department employees is carried out by the head of the department in accordance with job descriptions and these Regulations. IV. Functions 1. Organizing and ensuring control over the implementation of activities aimed at creating safe and healthy working conditions at the enterprise. 2. Organization of the development and implementation of more advanced designs of fencing equipment, protective devices and other safety equipment. 3. Monitoring compliance with legislative norms, safety regulations and industrial sanitation in projects of workshops under construction and reconstruction. 4. Management of the development of new and revision of outdated instructions and leaflets on safety and labor protection, drawing up training programs for workers in safe work methods. 5. Ensuring introductory safety training for employees entering the enterprise, organizing repeated training in the workshops and services of the enterprise. 6. Organization of propaganda of safety, labor protection and industrial sanitation through teaching rooms, as well as by holding lectures, conversations, arranging exhibitions, showcases, stands, distributing rules, instructions, memos, showing films, etc. 7. Monitoring compliance standards of sanitary and hygienic, safe working conditions and industrial sanitation in workshops and other structural divisions of the enterprise. 8. Participation in the investigation and analysis of the causes of industrial injuries and occupational diseases, in the development of measures to prevent and eliminate them. 9. Control over the expenditure of allocations for occupational health and safety. 10. Ensure reporting on occupational health and safety. V. Relationships of the labor protection and safety department with other divisions of the enterprise 1. With the logistics department Receives: information on allocated and sold funds for workwear, safety shoes, and protective equipment. Represents: calculations of needs and requests for workwear and safety footwear, protective equipment. 2. With the department of labor organization and wages, laboratory of economic analysis Submits: a report on industrial injuries and the implementation of the plan of health measures. 3. With other departments of the enterprise Receives: technical documentation for conclusion regarding the inclusion of safety regulations in it. Represents: conclusions on technical projects and technical documentation regarding the inclusion of safety regulations in them. 4. With the permanent production meeting of the enterprise Receives: proposals on safety, labor protection, industrial sanitation and the best use of allocations for these purposes developed at the meetings of the permanent production meeting. Presents: methodological information on ensuring safety, labor protection and industrial sanitation. VI. Rights 1. Require departments of the enterprise to submit materials (information, plans, reports, etc.) necessary to carry out work within the competence of the department.. 2. Communicate with medical institutions, research organizations on labor protection issues and safety precautions. 3. Conduct an inspection of the state of labor protection, safety regulations and industrial sanitation in all departments of the enterprise, and at any time of the day. 4. Prohibit the performance of work in conditions dangerous to the life and health of workers, with immediate notification of the chief engineer or director of the enterprise. 5. Prohibit the operation of equipment and tools in violation of safety and industrial sanitation norms and regulations. 6. To remove from work, through the heads of departments, persons who violate work safety rules. 7. To encourage employees for good work and achievements in the field of labor protection, safety regulations and production culture, to make proposals to bring to justice in the prescribed manner those guilty of violating labor protection and safety regulations. 8. The instructions of the department within the scope of the functions provided for by these Regulations are mandatory for management and execution by divisions of the enterprise. VII. Responsibility 1. The head of the department bears full responsibility for the quality and timeliness of fulfillment of the tasks and functions assigned to the department by these regulations. 2. The degree of responsibility of other employees is established by job descriptions.

Can a HSE engineer work part-time?

Yes, despite the fact that the duties require constant monitoring, the service employee has every right to claim several hours of work, if at the same time he completely, in full and within the established time frame, performs the tasks assigned to him.

In addition, he can claim benefits and compensation for the harmful effects of production, since although he does not work in the workshop, he spends some time there as part of his duty.