There are many types of work that is dangerous from the point of view of the possibility of a fire, carried out both in buildings, structures, on the territory of mining, procurement, industrial, agricultural enterprises, construction sites; and in buildings for various public purposes, residential buildings during reconstruction, planned, emergency repairs, replacement of sections of engineering systems/communications, roofs.

These include the following types of events:

- Cutting metal structures, rolled metal with power tools, because this is accompanied by the scattering of hot drops and sparks with high energy sufficient to ignite organic substances/materials, while spark arresters have not yet been invented for such situations.

- Heating of parts/products, mounting structures using open fire during assembly/installation.

- Any types of gas-electric welding work, as well as cutting structures, products, scrap metal using this type of equipment.

- Using equipment for cutting scrap metal, building and installation structures using flammable gases - propane, acetylene, liquids - gasoline, kerosene.

- Soldering of various metals.

- Heating of bitumen and other mastics/compositions used for construction/repair of roofs, waterproofing of building structures, utility pipelines/systems.

If similar types/types of hazardous work are carried out in specially designated premises for these purposes, places - welding stations, workshops, areas of workshops/productions, equipped in accordance with the norms/rules of industrial safety with primary means for fighting fire - carbon dioxide, powder, air-foam fire extinguishers, boxes with sand, fire-resistant fabric/felt, properly equipped PCs, as well as on the territory, in buildings, structures of private households, construction sites; then they do not require any permitting documents.

If any type of such work is carried out in temporary places, with the exception of the above-mentioned situations, then in accordance with the PPR that determines the fire safety regime on the territory of Russia, the head of the enterprise/organization, or an official appointed by him, is responsible for the fire safety of the building, workshop, site , the premises are issued with an approval order (OA) for hot work (OR).

What is this document for?

The design of the outfit has preventive and legal significance. Despite the measures taken, an emergency situation is still possible. According to the labor protection rules, it is necessary to conduct an investigation at the legal level and then a clear answer will be received to the question: does the work permit require a permit for welding work.

This document has legal significance, and it is drawn up in the interests of those persons who are responsible for the correct performance of dangerous work. One of the arguments in their favor when analyzing their actions is “forewarned is forearmed.” Having access to welding work will indicate that they have fulfilled their duties.

The preventive value of observing this formality is invaluable. When a person must perform such dangerous actions every day due to his profession, his attention may become dull. Receiving an outfit mobilizes his attention, forces him to exercise reasonable caution and can save his health, and maybe even his life. Not to mention the fact that property may be significantly damaged and, as the culprit, he will have to pay significant sums of money.

Definition and types

In the labor protection system, such work is called hot work, among them the following are usually distinguished:

- electric or gas type welding;

- welding of metal structures;

- metal cutting with liquid fuel, electric or gas devices;

- mechanical cutting;

- heating masses of bitumen over an open flame.

When performing fire hazardous work in specially designated areas, for example, in workshops or workshops, the premises must be equipped with primary fire extinguishing means - fire extinguishers, containers with sand, special cloths. If these conditions are met, there is no need to obtain permits.

At temporary facilities not intended for hot work, such labor tasks can also be performed, but only after the responsible person has issued a work permit.

What needs to be done before filling out the work order

Before you start filling out the document, you must check that the requirements of the rules for safe conduct of metal welding work are met. Welders with qualifications corresponding to the complexity of the work ahead can be admitted to them. They must have identification with them confirming this.

The work manager must draw up a clear plan for the sequence of actions and familiarize all persons involved with it. Safety training specific to the specific task conditions must be provided. It may well be that even experienced welders will encounter this option for the first time and this will expand their knowledge. Instructions must be carried out by persons authorized to do so. After the end of the lesson, students must sign in the registration log in the column provided for this.

Workers must be provided with personal protective equipment, consisting of a suit made of material with high fire-resistant properties, gloves, special shoes and a protective mask.

Care should be taken to ensure that all workplace safety measures are implemented. It is necessary to check whether there are fire extinguishers on it. When carrying out work indoors, an exhaust system must be equipped there. The danger zone must have a fence with identification signs. It is necessary to check the serviceability of the equipment used. The time elapsed since the last verification should not be overdue. You can do a test run.

Current restrictions

When carrying out fire and explosion hazardous operations, a number of restrictions apply:

- when performing hot work, clothing should not be contaminated with flammable liquids;

- Employees with appropriate qualification certificates must be allowed to perform tasks;

- It is prohibited to work in closed spaces filled with explosive vapors;

- The welding machine and other equipment cannot be powered directly from the distribution network.

There is also a requirement for carrying and angling cylinders. All actions must be performed in full accordance with safety precautions.

Filling rules

The work permit for welding work must be issued not by hand, but in printed form. There are different options. It can be printed on plain A4 paper. Continuation on the reverse side of the sheet is allowed. If several sheets are filled out, they must be stapled together. In this case, a sample work order for welding work is used. A reputable enterprise can develop a letterhead, the use of which saves time and makes work easier.

The work order is filled out by an authorized person. It is performed in 2 copies. One of them is given to the contractor under his signature, and the second remains with the manager and is filed in the file.

Filling out the items can be done manually or on a computer. When filling out manually, you must do this in legible handwriting with a pen filled in with a color that is clearly visible on the paper. The use of a pencil or fine marker is not permitted. The paper should be free of dirt and oil stains.

It is necessary to ensure that there are no grammatical errors. It is especially important that last names and initials are written correctly, otherwise the document will become invalid. If errors are found, a correction record is not allowed. The document will have to be reprinted or filled out again manually.

Preparing to start work

Before carrying out such operations, an action plan is drawn up and, if possible, all flammable materials are eliminated. Additionally, measures are taken to prevent the scattering of sparks, and warning signs are placed along the boundaries of the danger zone. Clearly visible signs are placed in places where gas cutting is carried out. For this you can use, for example, white paint or chalk. Pipeline cavities and other communications where hot work is planned are cleared of flammable liquids and materials. At the same time, they are separated from active areas using special plugs. Appropriate notes are made in the journal regarding the installation and removal of plugs.

When performing preparatory measures, the starting parts of all electrical installations are de-energized, and measures are taken to prevent their unexpected start-up. Each specialist involved must undergo training and be provided with fire protection equipment. After which his workplace and tools are checked. The issuance of a work permit for hot work is possible only after complete completion of preparatory activities.

Filling out the form

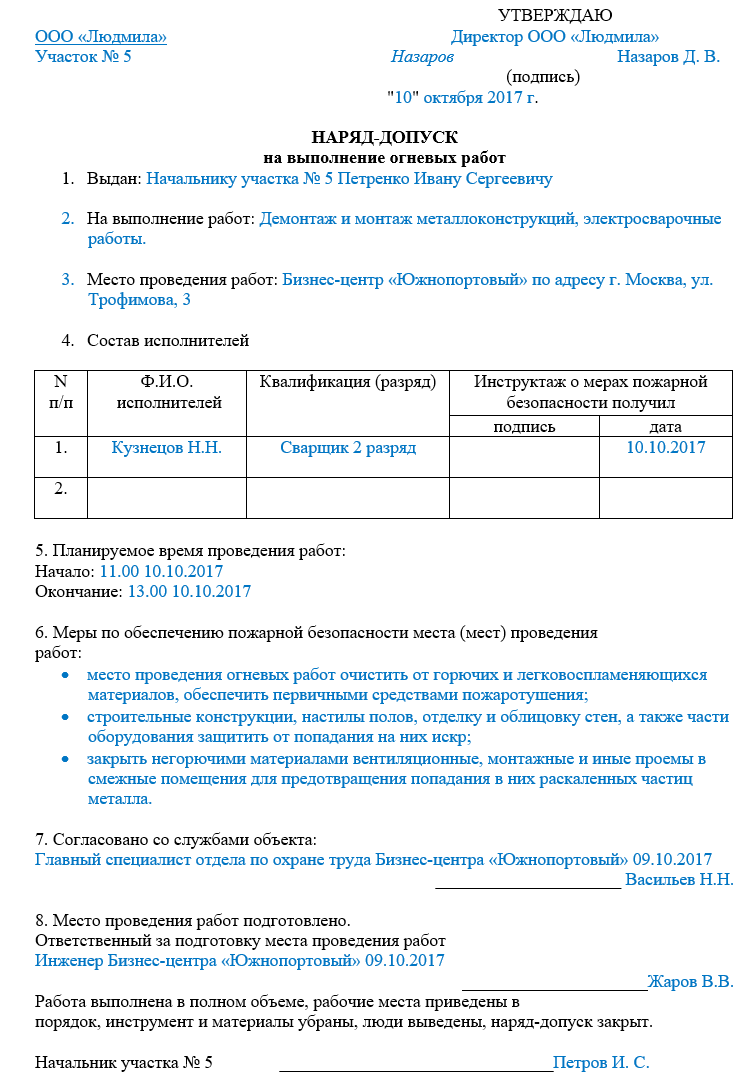

The work permit for welding work is a type of permit. This places special demands on its content. Let's look at how to do this correctly using the following example of a sample of filling out a work permit for welding work.

At the top of the sheet, on the left side, the full name of the enterprise or organization whose forces will carry out the welding work and its specific section must be indicated. On the right there should be the inscription “APPROVED”, indicating who exactly is approving with his signature and decoding of his last name. Space must be left for the approver's signature and date.

Below in the center the name of the document should be printed in large letters. In addition to mentioning hot work, more specific things are allowed. For example, “Permission work order for welding work.” The first paragraph indicates to whom the document was issued and his position. In the future, he will be responsible for the correct execution of welding work. In the second paragraph, it is necessary to indicate the nature of the work being performed, and there may be several of them, as in the sample under consideration.

The third indicates the exact address of the place of work and the name of the organization to which these services are provided. An entire table is devoted to the fourth point. Each column indicates a specific employee, his profession and his current rank. Next to his name, he must put his signature certifying that the briefing was carried out and the date of it.

In the fifth paragraph, the specific start and end times of the planned time allotted for completing the task are entered. The sixth lists the necessary fire safety measures. The seventh indicates with whom this document was agreed upon. The eighth sign is signed by the person responsible for ensuring that the work site is prepared.

After completing the task, a corresponding note is made about this. It indicates the final activities carried out, makes a note about the closure of the order and puts the signature of the person in charge.

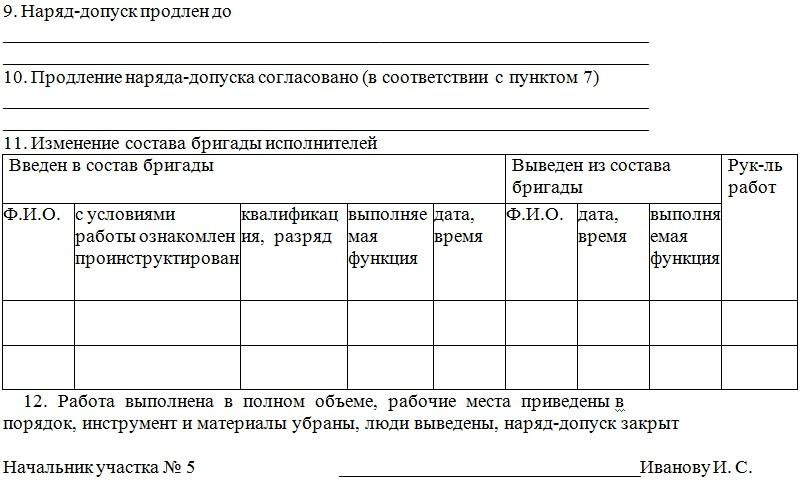

In addition to these main points, additional ones can be filled in. The fifth paragraph indicates only approximate times. If the welder does not meet it, then the ninth paragraph must be filled out, which indicates until what time the welding work order has been extended. It is necessary to take into account that one shift is the longest extension period.

In the tenth paragraph, a mark is placed on agreement with the official specified in the seventh paragraph. If there has been a replacement of welders, this is indicated in the tenth paragraph, presented in the form of a table. It records all the changes that have occurred.

It is necessary to ensure that all required signatures are provided. Only in this case will the work order for welding work acquire the status of a valid document. A sample work permit for welding work will help you fill out this document correctly and quickly.

Necessary requirements for registration

A work permit for welding tasks is never issued freely, a strict form will be required, and any authorizations made without this form are considered invalid. Sometimes production makes their own forms. This is acceptable, but only if all parts of the base version are preserved.

Before registration begins, the workplace is prepared and inspected. First, the work area itself is checked, then the equipment located in it, and then personal protective equipment. If something is faulty or damaged, a permit can be issued only after all defects have been eliminated.

Who issues the permit?

The issuance of this document is the prerogative of a specialist in the field of labor protection. He must have all the specific knowledge in this area. This employee must have a certificate of receipt of appropriate education. If there is no such specialist on staff, the head of the department is authorized to issue the document.

The permit is issued for one work shift. If long-term welding work is to be carried out, then a separate work order will have to be issued for each shift. The absence of such a document may be regarded as an administrative violation.

When performing what actions is it issued?

Issuance of a document on welding work is mandatory in the following cases:

- in case of carrying out activities near activities related to welding of various types, in order to avoid fire or harm to health;

- when carrying out welding work with devices of various types to comply with safety standards at the enterprise, to prevent fire and harm to equipment and the health of employees;

- when eliminating the consequences of an emergency situation in an organization or a state of emergency (man-made, environmental or other disaster) associated with the use of welding machines;

- when cutting metal, soldering various metals, working with bitumen compounds.